Degassing Vacuum Applications

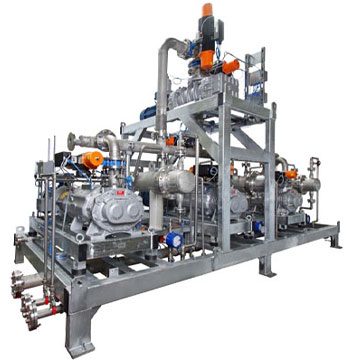

Our product portfolio consists of a complete range of engineered systems centred around reliable vacuum technologies. NASH provides tailor-made solutions for the following degassing applications:

- The removal of CO2 and other impurities in the production of purified water

- The removal of unwanted gasses to improve drugs and fine chemicals quality.

- The removal of gasses in the production of gelatin capsules, plastics, resins, glues, adhesives and pastes.

Degassing is not the most common application for chemical dry pumps, (CDP), although there are some important niche applications, including degassing of:

- Extruders (for production & fabrication of plastics)

- Fatty acid deodorization

- Resins

- Paints and polymers

- Glues and adhesives

- Glycols and glycol mixtures

- Synthetic fluids such as ester amides and other esters, silicone oils, fluorocarbon oils, (Fomblin)

- Transformer and switchgear oils

- Turbine lubrication and seal oils

- Hydrocarbon oils in general

Discover more about degassing vacuum applications by clicking the cards below.

USA (EN)

USA (EN)