The Rapid Growth Inside the Renewable Natural Gas Industry

As global energy dynamics shift towards sustainable practices, the Renewable Natural Gas industry stands at the forefront, experiencing unprecedented growth and making significant strides towards a cleaner, greener future. The momentum within the RNG sector is not just a trend; it's a testament to the industry's resilience, innovation, and fundamental role in addressing environmental challenges.

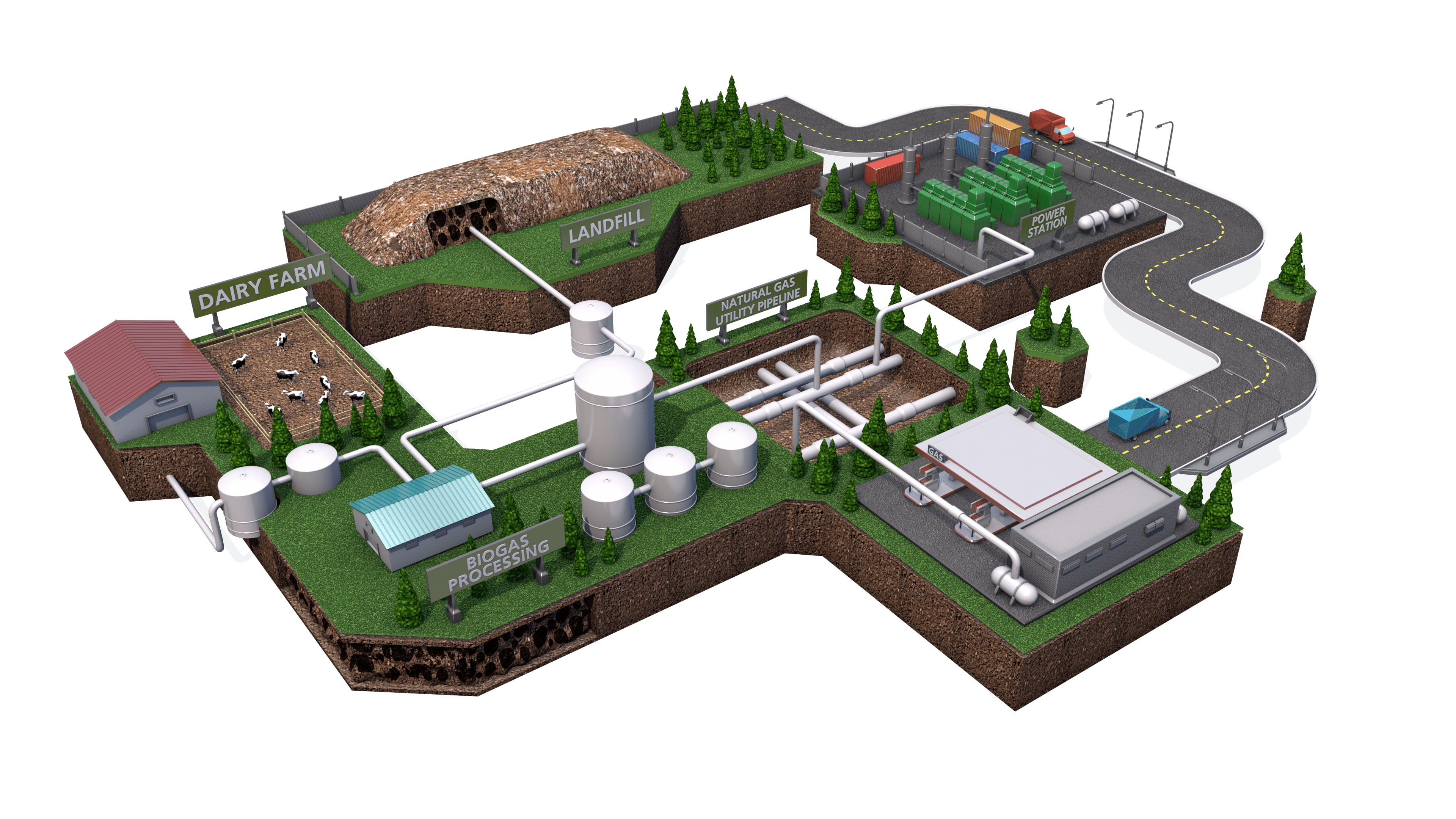

The renewable natural gas industry is witnessing a profound paradigm shift driven by an increased awareness of climate change and the urgent need to transition towards cleaner energy sources. RNG, produced from organic waste, landfill emissions, and agricultural byproducts, represents a sustainable alternative to traditional fossil fuels.

Governments worldwide are recognizing the importance of RNG in achieving carbon reduction goals. Supportive policies, incentives, and subsidies are pushing the industry forward, encouraging investments in RNG projects and infrastructure. This positive regulatory environment is a key driver of the industry's remarkable growth.

Beyond its environmental advantages, RNG offers economic benefits to both producers and consumers, hence resurgence made possible with a new wave of technological innovations. The reduction of greenhouse gas emissions, job creation in the RNG value chain, and the potential for energy independence are contributing to the industry's attractiveness and fostering sustained growth.

The growth within the renewable natural gas industry is not merely a statistical improvement; it symbolizes a collective commitment to a sustainable and strong energy future.

Choose Nash - Choose Efficiency, Reliability, and Sustainability:

Make Nash your partner in advancing Renewable Natural Gas operations. Our liquid ring vacuum pumps and compressors are the ideal solutions for overcoming challenges and maximizing the potential of the RNG industry. Contact us today to discuss your specific requirements and experience the Nash advantage for a sustainable future.

USA (EN)

USA (EN)