Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

Thank you for your ongoing support and interest in Hoffman and Lamson Industrial Central Vacuum and Engineered Vacuum Systems (EVS).

As of July 2022, Hoffman and Lamson has decided to focus on enhancing our aftermarket services while discontinuing the development and manufacturing of new Central and Engineered Vacuum Systems. This change aligns with our internal business priorities, allowing us to better serve you.

We are grateful for the loyalty and trust of our valued EVS customers, and we want to assure you that our commitment to your satisfaction remains unwavering. We will continue to offer comprehensive support for parts, oils, and accessories to ensure your existing systems operate at their best. If you require product support or parts, please don't hesitate to click the appropriate link below.

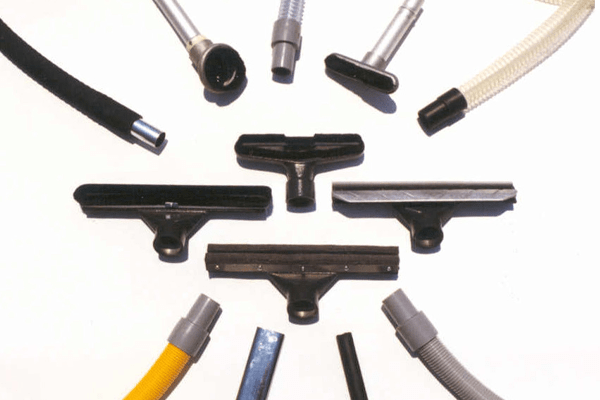

We offer a wide range of commercial, industrial, and utility vacuum hoses, floor rods, and hand tools to the vacuum marketplace. Our vacuum hoses are available in a variety of materials such as flexible plastic, heavy-duty rubber, crush-proof plastic, and more!

We offer a complete line of Smooth Flow tubing and fittings, which help simplify installation and reduce piping loss. The lightweight tubing and fittings provide efficient and cost-effective piping and are selected worldwide in place of heavy cast iron piping. Available in many different sizes, gauges, and materials, Hoffman & Lamson has every tubing and fitting your operation will need.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.