Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Automatic ropeless tail threading concepts are safe, reliable and maintenance free. Technology can be applied from the wet end to the reel.

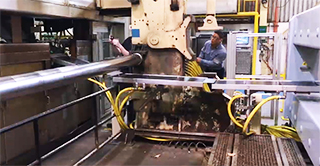

Today, operator safety is a must – and one of the top priorities in every paper and board mill. However, many mills still carry out tail threading with a conventional carrier rope system that presents serious hazards for the staff.

The benefits of ropeless tail threading with Runtech Systems’ technology are numerous. It improves operator safety significantly while also shortening tail threading time during web breaks by up to 80% to increase production. In many cases, the technology enables mills to increase machine speed, which would not be possible with manual tail threading without risking operator safety. Also, thanks to the automated process, operators can focus on other tasks. All these benefits are reflected in a short payback time.

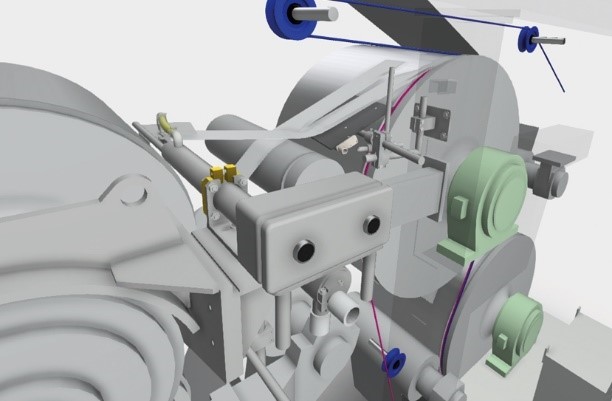

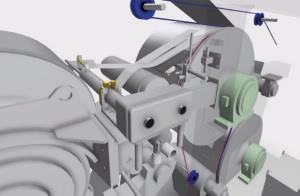

Conversion from a conventional rope carrier system to a ropeless one is fast, taking from only a few days to one week. It can be carried out in several parts, for example, over three years during planned machine shutdowns. To speed the project up and consider all the details, we create a 3D scan of each paper machine. These scans are used in engineering and to write assembly instructions for the mill. Thanks to accurate scanning, measurement errors can be avoided.

If a machine has a challenging geometry, it is possible to test the tail threading equipment with the customer’s own paper or board on Runtech Systems’ demo pilot machine.

Press RunShooter delivers the tail directly from the center roll to a separate press or from a separate press to the dryer section

Very efficient release from the dryer cylinder surface due to the ‘Release Blow’ technology with TailBlade mini doctor. Possibility also to install directly to the existing doctor beam.

RunShooter technology can be used for example before the size press, Clupak and in the pope reel area

Paper Machine Runnability and Tail threading RunPro

Runnability orientated RunPro offers web stabilizing, machine geometry modifications and ropeless tail threading solutions to eliminate runnability problems and to ensure fluent paper making process.

Web stabilizing and tail threading solutions are safe, reliable and maintenance free resulting in significant benefits that are reflected in a minimal payback time.

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness. Our main target is to bring notable energy savings and highly improved process efficiency for board, tissue and paper mills.

Runtech's patented solutions include energy efficient vacuum system and heat recovery optimization, runnability optimization, dewatering, doctoring and cleanliness optimization as well as ropeless tail threading, including related services, spare parts and paper machine audits and consulting.