The Basic Working Principle & Design

In a rotary vane compressor, compression is accomplished as centrifugal force extends vanes from slots to form individual compression cells. As the cells move around a stator, the trapped air is compressed and expelled from the compression area.

These compressors offer up to 100,000+ operating hours due to their simple integral design. They are all direct drive driven with a shock-absorbing coupling system. This eliminates the need for speed increasing gears and over tensioning belts. Maintenance costs are reduced by simple construction and grouped service components. Rotary vane compressors run at a conservative slow speed, making them extremely reliable and extending the life of the machine.

Where are these compressors best suited?

Rotary vanes are generally very quiet making them a strong consideration for point-of-use compressor applications. Even without an enclosure, lower HP rotary vane compressors are very quiet compared to other options.

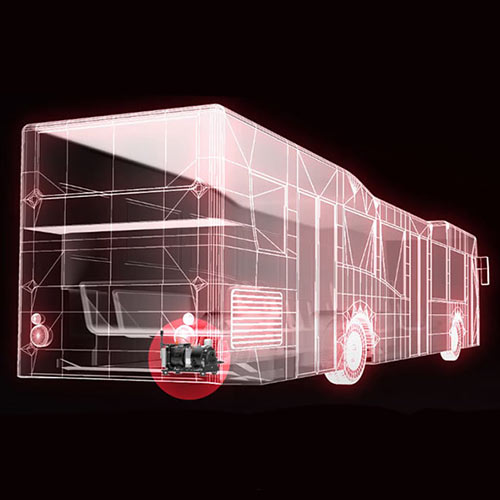

They are engineered to meet the most stringent of specifications and are ideal for 100% duty cycle applications. Rotary vane compressors are easy to install and maintain. They are designed for a wide variety of applications including automobile, body shops, wood working, dentistry, laundry, packaging and machine tools.

Global (EN)

Global (EN)