Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

Grades: Specialty and industrial packaging

Speed: 900 m/min

Width: 6.6 m

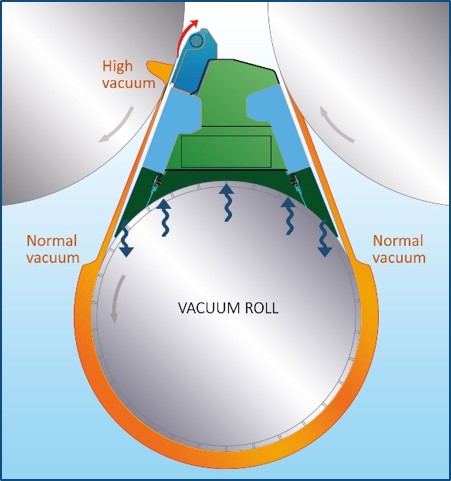

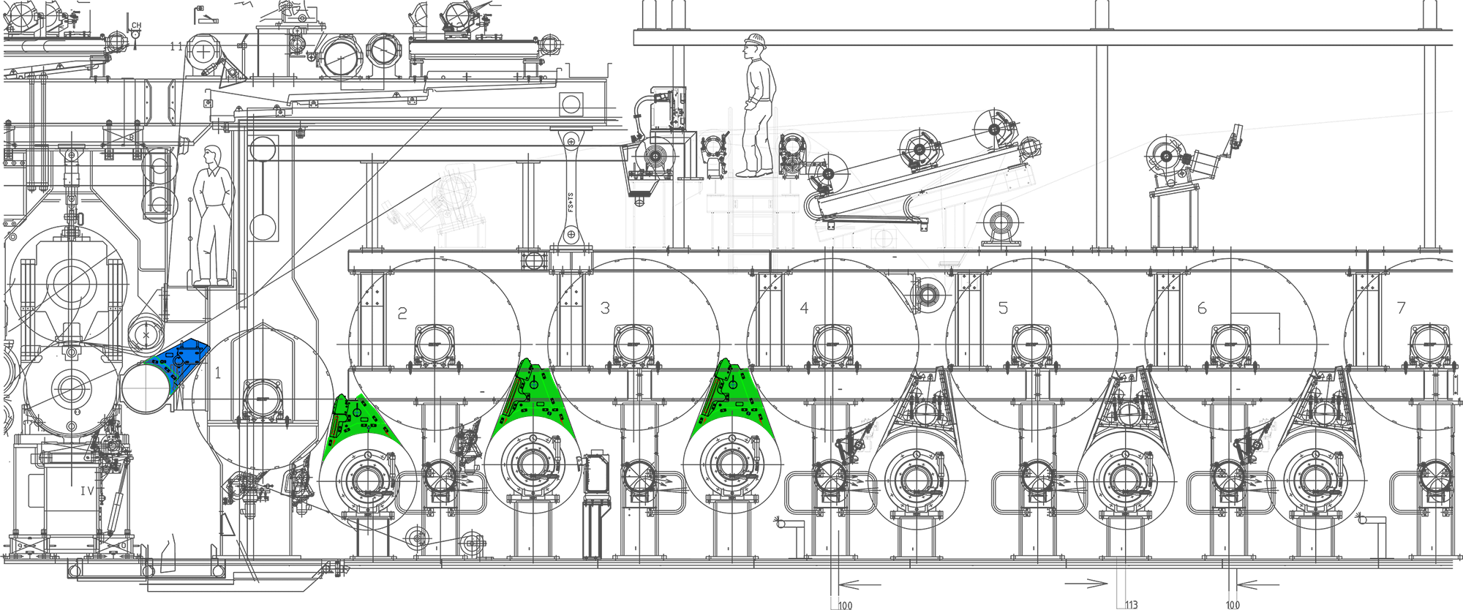

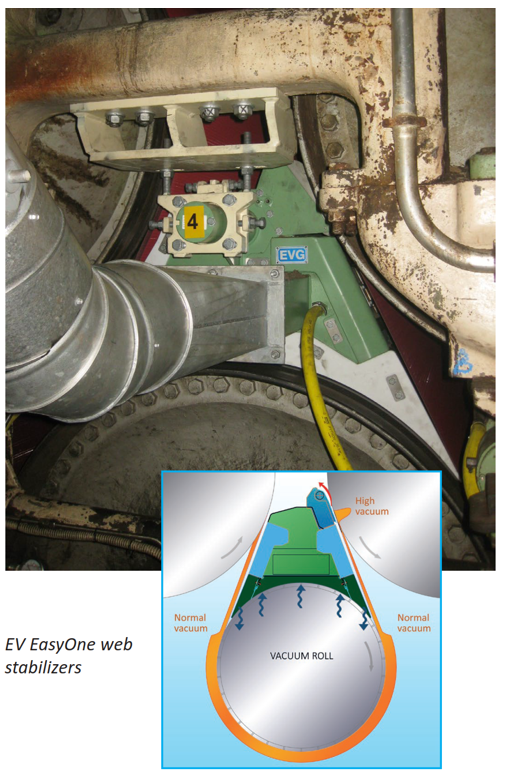

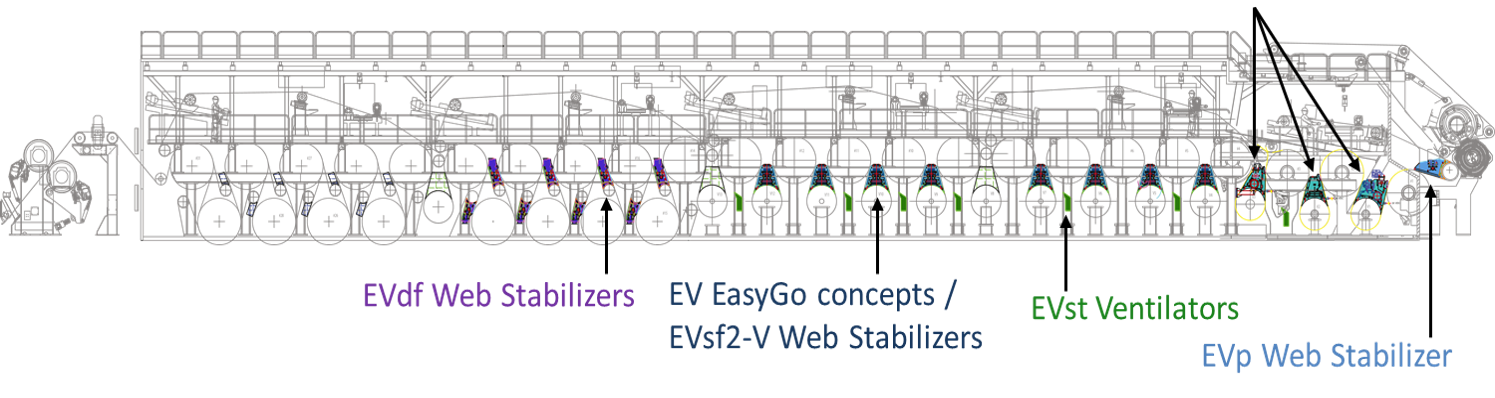

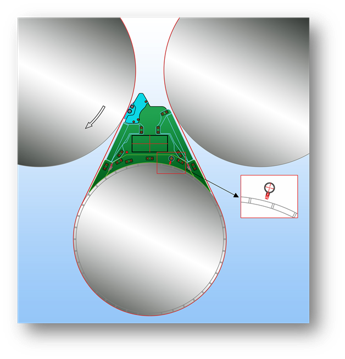

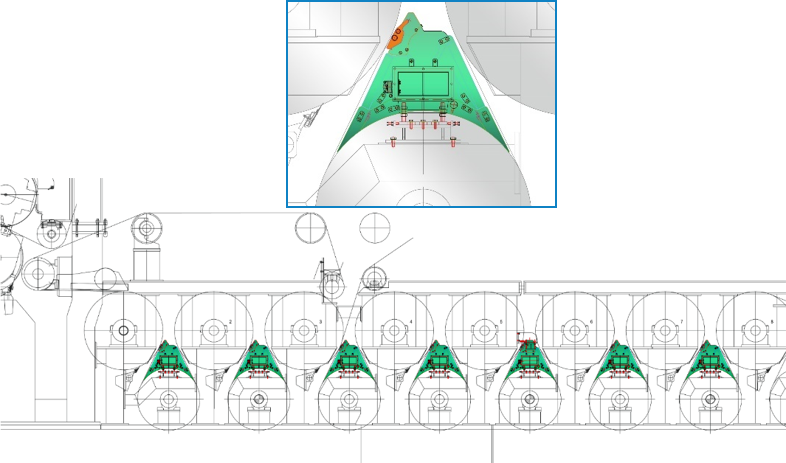

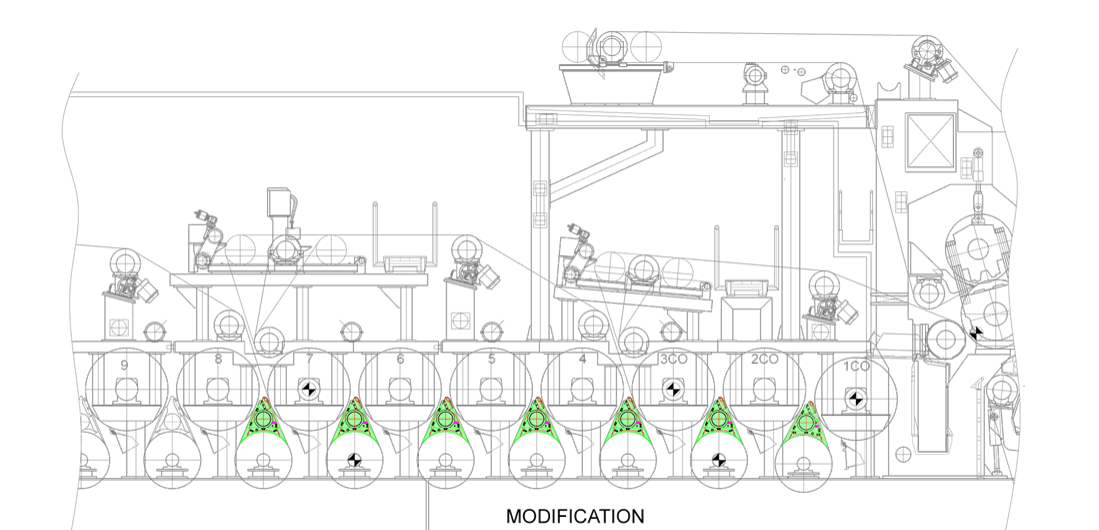

Press section web stabilizer and EasyOne web stabilizers:

In 2016 EV Group and Runtech Systems made a significant upgrade to Hamburger Hungaria Dunaújváros PM 3 Containerboard machine. The upgrade consisted of followings:

Grades: Fluting, Testliner

Speed: 1200 m/min

Width: 5.6 m

"Since start-up in June [2014], we realized significantly improved runnability, although we did not even exploit the full potential of the new stabilizers because of a lower tension of the dryer fabric. The amount of web breaks in the dryer section has already decreased noticeably."

-Mr. Wolfram Gerspach, Production Manager

Paper grade: Fluting & Testliner

Design speed: 1800 m/min

Basis weight: 70-140 gsm

Trim at reel: 7900 mm

Year built: 2012

The installation has given Dunaújváros PM 3 a whole new set of tools to further develop and optimize the productivity and quality.

Investment payback period is feasible due to increased production efficiency and decreased material costs.

Specific energy consumption per ton decreases, yearly production increases, and product quality improves.