What is Compressed Air Treatment and Why Is It Important?

Compressed air treatment is a method that involves purifying and dehumidifying the air before it enters the compressor. During compression, air accumulates moisture, oil, and other contaminants that can have a negative impact on equipment performance and product quality.

An efficient and intelligent compressed air system goes beyond high-quality air compressors. It is a combination of a range of expertise and products related to air generation, filtering, drying, condensation, and purification. With an efficient air treatment process, your system will experience extended equipment lifespan, improved operational efficiency, and the preservation of product integrity.

An essential part of compressed air treatment is air quality testing, which guarantees the purity and safety of your industrial process air. It involves the regular analysis and monitoring of compressed air to identify and quantify any contaminants present in the system. Air quality testing uses specialized equipment and analytical techniques to assess the concentration levels of various contaminants in compressed air.

Regular testing allows for early detection of potential issues, enabling you to take timely corrective measures. This proactive approach helps prevent costly breakdowns, production delays, and product defects, ensuring smooth operations and reducing downtime.

Types of Compressed Air Treatment

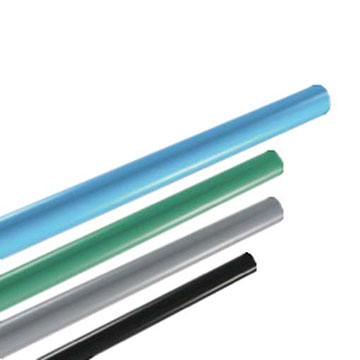

Compressed Air Treatment has a diverse range of purposes, compressed air necessitates adherence to distinct quality standards, catering to specific functions. Different methods can be used to remove the moisture content of compressed air. Gardner Denver compressed air types include the following products:

USA (EN)

USA (EN)