Industrial Air Compressor Selection: The Importance of a Tiered Product Offering

As the term implies, a tiered product offering is one that offers something like “good, better and best” for a given product.

We see this every day in the goods and services that we purchase as consumers. First, there is the base model car that comes equipped with air conditioning and power windows but not much else. Next, for a few dollars more, you can upgrade and include powered and heated seats, tinted windows and a fancier stereo. Then there is the model that has it all – sunroof, sporty tires, more airbags than seats and all sorts of other goodies that make the Owner’s Manual the size of an encyclopedia.

When it comes to air compressors, a tiered product offering can be looked at in a few different ways. As a result, the following should help you navigate your next compressor purchase more effectively.

Tiered Technologies

Here we are using the term “tiered” to refer to a company that has multiple compressor technologies to offer. It is not an issue of good, better, best, but instead selecting the correct technology for your application.

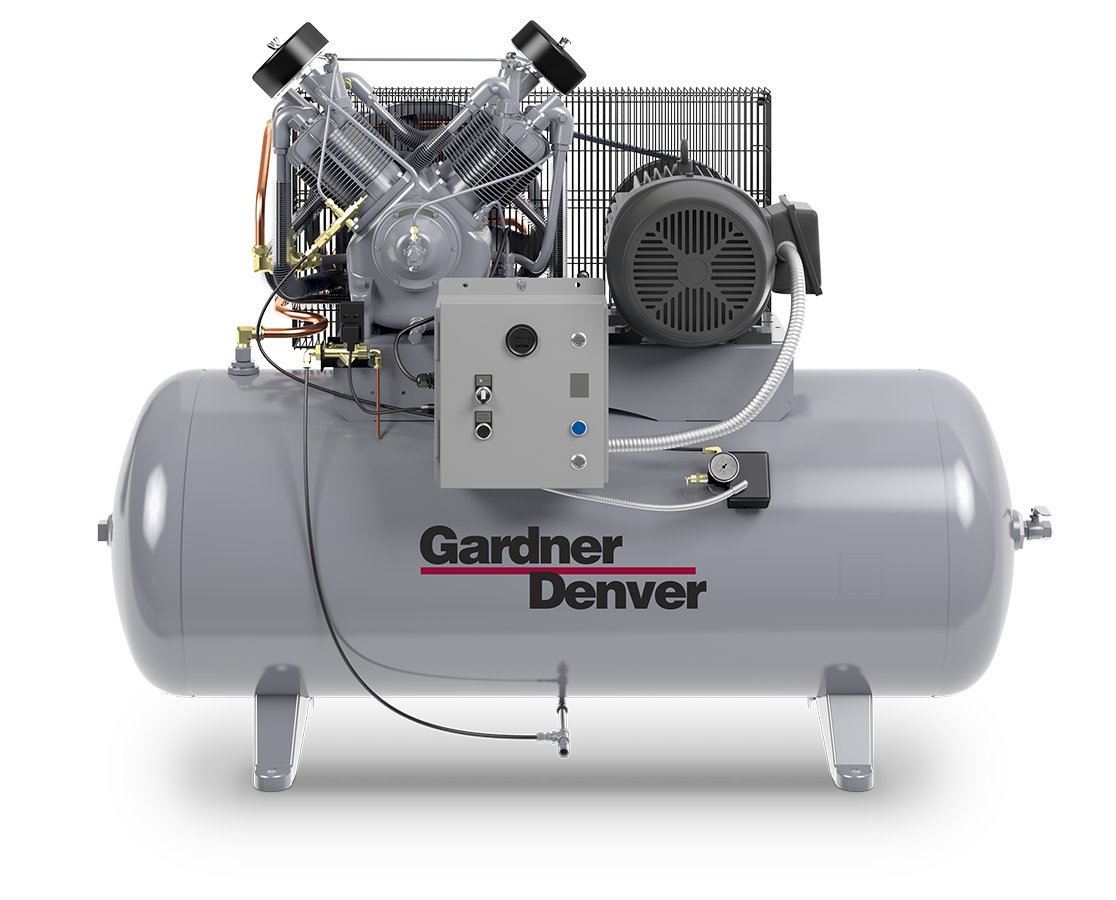

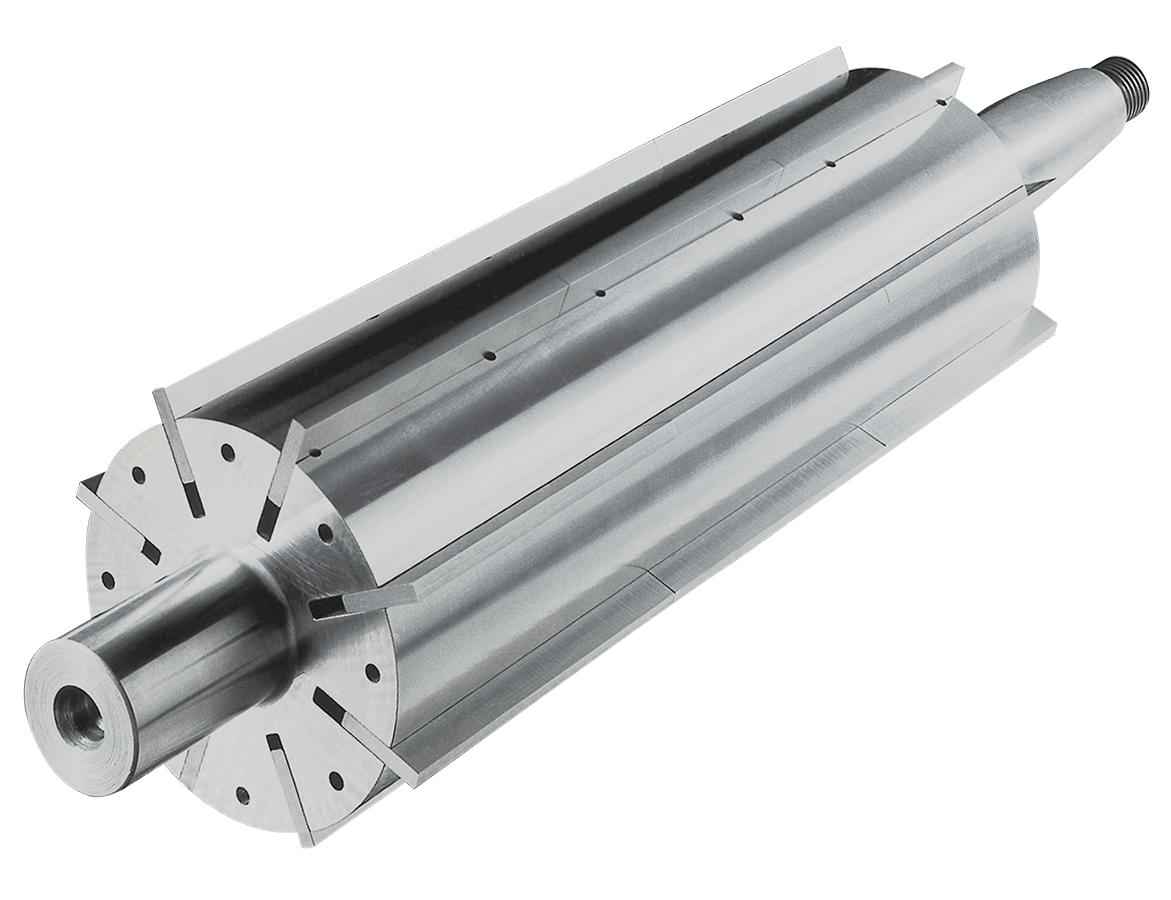

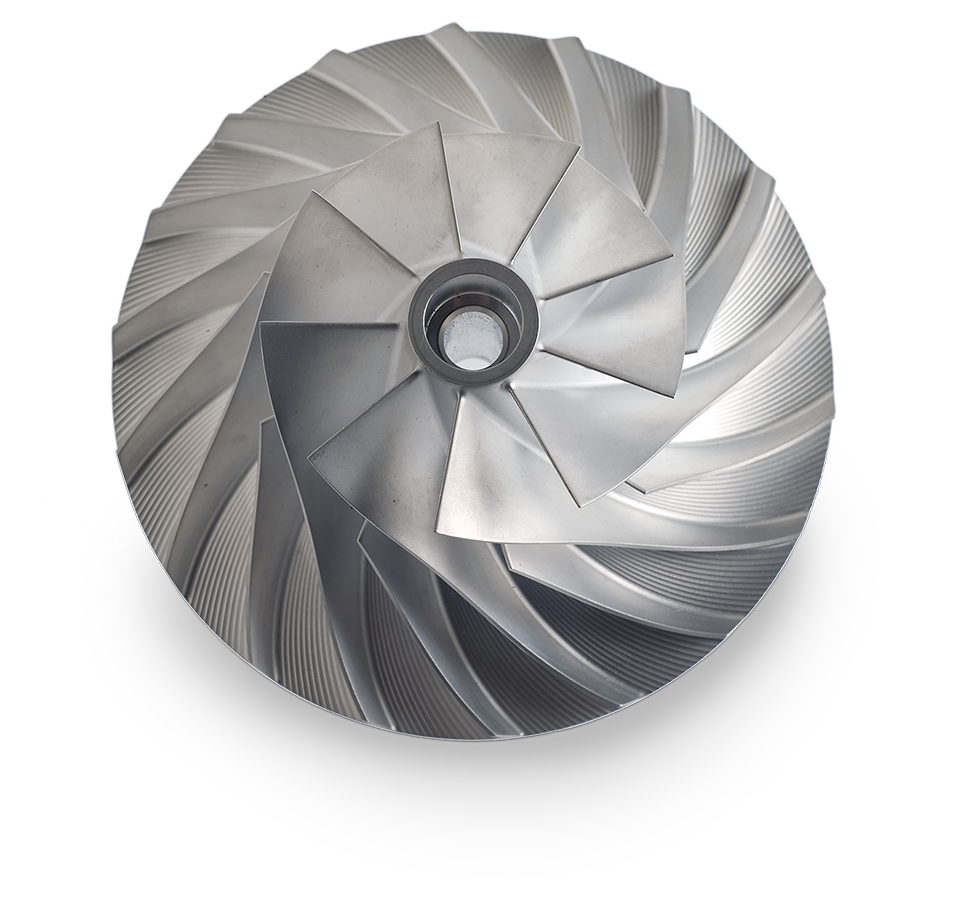

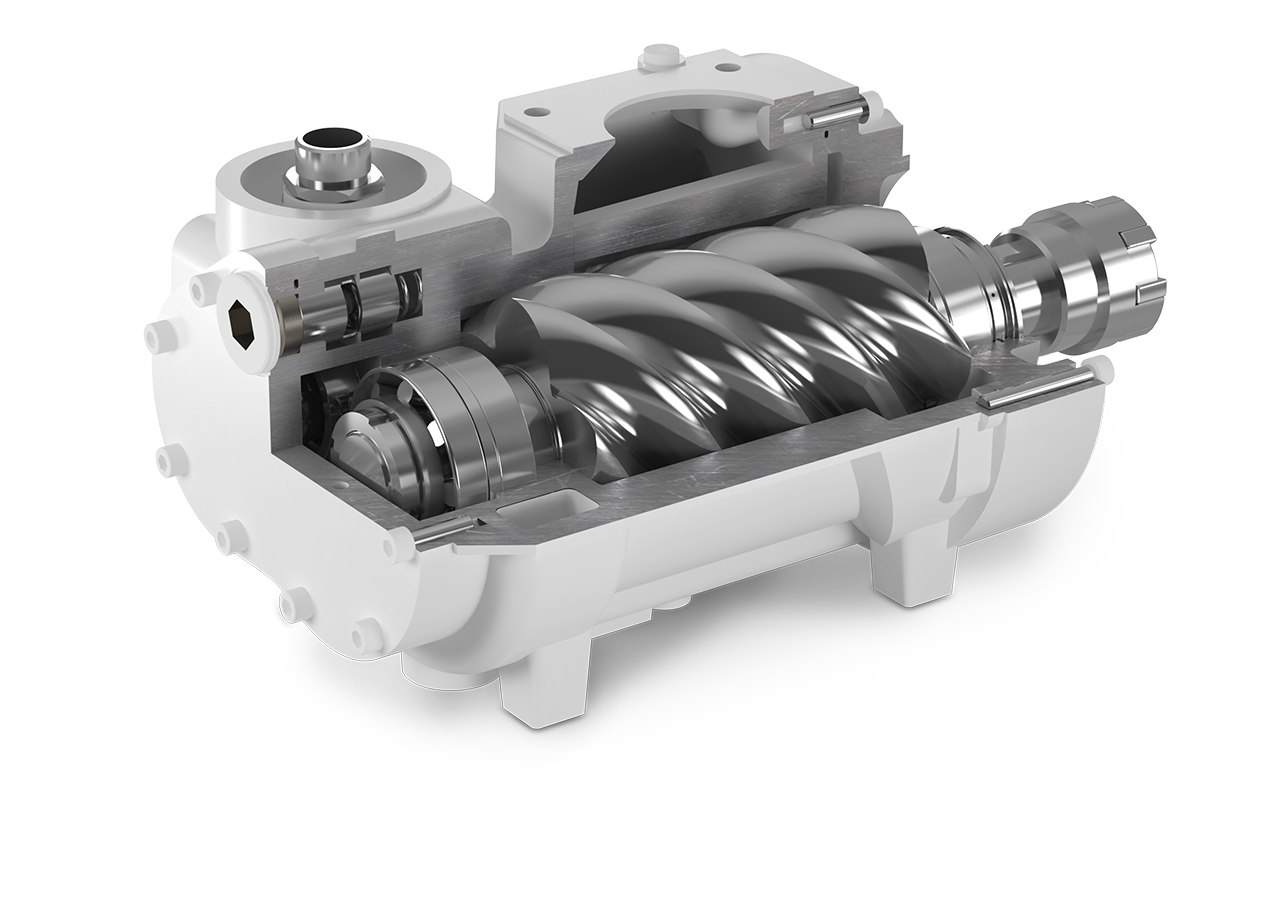

Typical compressor technologies include reciprocating, rotary screw, rotary vane, centrifugal, high-speed centrifugal, scroll and a few others. One technology is not right for every application. As an example, at low HP ranges such as 10 HP and below, several technology choices will work.

Usually one technology will outperform the others depending upon the specifics of the application and needs or wants of the purchaser. If the air requirement is very intermittent, the reciprocating compressor is likely the best choice. As the application specifics change, the technology choice may change as well.

USA (EN)

USA (EN)