Select Your Country/Region

Current Region:

USA (EN)

USA (EN)

Choose a different country or region to see the content specific to your location

- gd-about-us

- News

- Gardner Denver at the IFAT 2016

How can we help you?

Gardner Denver is presenting a wide range of technical solutions for generating pressure and vacuums at the IFAT 2016. With an impressive variety of versions, the company is responding to the trend for increasingly smaller batch sizes and to the varied demand for sophisticated energy-saving pumps and compressor technology for stationary and mobile use (Hall A3.237/336 and Hall B5.301).

Gardner Denver possesses a vast amount of expertise in fundamental environmental technology with famous global brands CompAir, Elmo Rietschle, Robuschi and Wittig. Internationally, this expertise is put to use in drinking water production, wastewater treatment, sewer cleaning and biogas production as well as recycling waste and reusable materials, with the aim of conserving resources through lower energy use and reducing emissions, with greater efficiency.

Tailor-made products offer great optimisation potential for wastewater treatment plants. The varied Gardner Denver range – which covers low pressure turbo compressors, screw and rotary piston compressors, side channel blowers, rotary vane and claw compressors, and vacuum pumps – provides all the equipment needed to achieve maximum energy efficiency when using different systems in combination.

The claw compressors from Elmo Rietschle cover a volume flow range of 60 to 600 m3/h at a maximum pressure of up to 2.2 bar during continuous operation. The ATEX version of this dry-running, contact-free technology is used in the field of biogas for gas extraction and recirculation in digesters.

The side channel blowers from the G-BH2 series represent a new device generation which is characterised by benefits such as reduced life cycle costs and high reliability. Their applications include digester gas and biogas compression as well as generation of blow air in wastewater treatment plants. For example, a bearing change only needs to be carried out after 40,000 operating hours. The compressors operate extremely quietly and can be used worldwide thanks to UL/CSA and IEC/EN certification. Ex versions according to ATEX also feature in the range.

With these Elmo Rietschle side channel blowers, the infinitely variable output control ensures energy-efficient operation and the housing is designed to ensure maximum flexibility for integration into customer-side systems. This series is also characterised by a considerably reduced noise level and compact, easy-to-install dimensions.

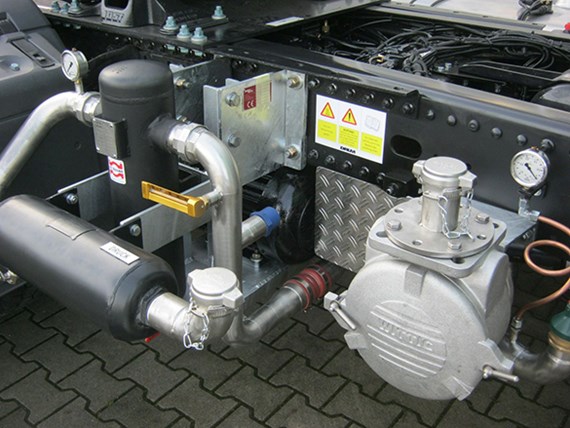

With a robust construction, low maintenance and a long service life, the Wittig rotary vanes have become widespread components which work around the clock in wastewater treatment plants, in biogas production and in waste disposal applications. The air-cooled rotary vane compressors, which are lubricated with fresh oil, and have volume flows of 120 to 540 m³/h and a positive operating pressure of up to 2.5 bar (g) are ATEX-certified (II 2G c IIB T2) and are used to compress biogas, landfill gas and digester gas, to name just a few examples. As an example of this product group, the L 50 GK type will be on display at the trade fair.

The oil-free ROBOX energy screw compressors are a new development, which offers considerable advantages, particularly from an economic viewpoint, when used in wastewater treatment. A pressure of up to 1000 mbar and flow rates of up to 4100 m³/h are reached with extremely economical use of energy. The efficient, demand-controlled output is achieved by the drive with the speed-controlled permanent magnet motor. Equipped with an integrated control cabinet and frequency converter, the communicative compressors are supplied ready for operation.

The ROBOX energy features a controller with the latest generation HMI touchscreen, which can be used to monitor the entire system. Remote monitoring is possible via an Ethernet cable or Internet communication.

Whether they are used for wastewater disposal and treatment in communal or industrial areas, the treatment of bio-waste and biogas production or for equipping special-purpose vehicles with vacuum pumps, one key aspect will play a particularly important role in the discussions at the IFAT: the control and sensor system must support the functions for system and vehicle technology automation solutions and be covered by valid certificates for the various regions.