Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

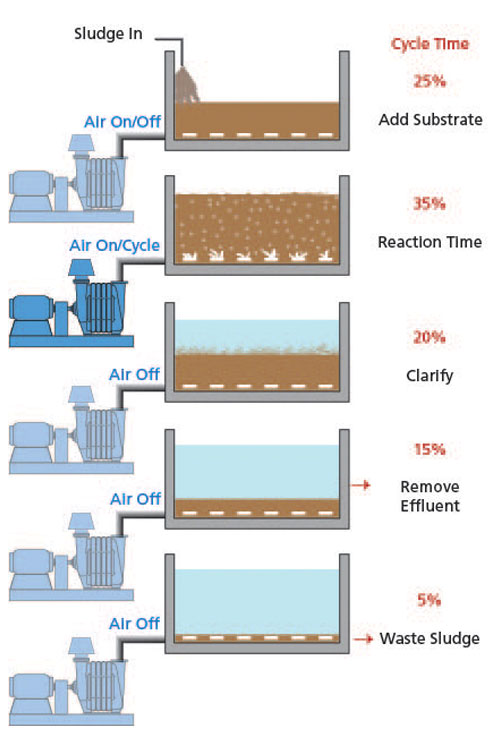

Activated sludge systems use suspended natural biological and bacterial growth to remove contaminants by absorption and subsequent breakdown. Sequencing batch reactors (SBR) are a special form of activated sludge treatment in which all of the treatment processes take place in the reactor and clarifiers are not required. This process treats the wastewater in batch mode and each batch is sequenced through a series of treatment stages.

Sequencing batch reactors or sequential batch reactors treat wastewater such as sewage in batches. Oxygen is bubbled through the wastewater to reduce both biochemical and chemical oxygen demand. In turn, this makes the effluent suitable for discharge to surface waters or use on land.

HOFFMAN & LAMSON blowers are the premier provider of engineered solutions for sequencing batch reactors across a wide range of applications. Our blowers deliver quality, reliability, value, and performance to serve many wastewater applications including, sequencing batch reactors.

While there are several configurations of SBRs, the process is similar for all. The basic installation consists of at least two identically equipped tanks with a common inlet, which can alternate the flow between them. The tanks have a “flow-through” system with raw wastewater (influent) coming in at one end and treated water (effluent) flowing out the other. While one tank is in settle/decant mode the other is aerating and filling.

Equipment is tested before reaching the customer or end-user. Thus, ensuring top quality and avoids unforeseeable issues or operational downtime. Therefore, upholding Hoffman & Lamson’s strong reputation as the global leader of engineered solutions and producing premier quality products efficiently and economically. There are over 100,000 HOFFMAN & LAMSON multistage centrifugal blowers and exhausters in operation worldwide.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.