Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Transport Solutions

- Industries

- Paper Industry

How can we help you?

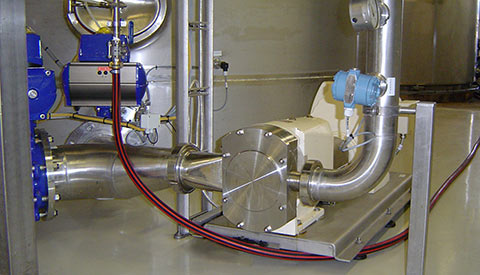

We offer a diverse range of rotary lobe paper pumps that are suited to numerous processes within paper mills and the paper production industry such as in the coating kitchen, size press, and coating section. SSP stainless steel pumps provide gentle handling of shear, sensitive media alongside a long service life with very little maintenance requirements.

The paper industry demands continuous, reliable operation with minimum maintenance. Many production facilities operate non-stop and any downtime can be costly. Gardner Denver Transport’s SSP pumps are optimised specifically for liquid transfer applications, offering cost-effective performance with minimal maintenance requirements. Furthermore, easy access to the pumphead minimises downtime for routine maintenance, resulting in increased uptime and reduced lifecycle cost.

Our range of SSP rotary lobe pumps provide reliable and proven pumping with minimum agitation for the paper industry. All pumped components are manufactured in stainless steel and provide low shear pumping for minimum damage to extremely shear, sensitive cultured media such as latex and starch based coatings.

The non-contacting design of the positive displacement technology also means that SSP pumps have the ability to handle abrasive media without causing wear or damage to the pumping component.

Our Series L pumps provide a hassle-free, simplified solution for your liquid transfer processes, providing a hygienic solution for handling low to high viscosity pumped media. For additional quality of life features, our Series S pumps provide the same high quality features of the Series L but in an optimised design to offer a longer life and increased durability for challenging applications.

Both Series L and Series S offer extremely sanitary operation and conform to the USA 3A Sanitary Standard and are EHEDG accredited, ensuring high levels of cleanliness for maximum peace of mind. Series L is suitable for CIP (Cleaning in Place), whilst Series S is suitable for both CIP and SIP (Sterilisation in Place).

Available in either a horizontal or vertical configuration, SSP pumps offer customers the flexibility to fit the pump to their exact infrastructure. Furthermore, a range of seal options of the highest quality help to reduce leakage.

Our application know-how and years of experience in working with professionals from the paper industry means that our range of pumps are designed and developed specifically to solve common issues faced by the industry. We can work with you to specify a pump that will offer efficient performance for your exact requirements.

Our product offering is backed by our installation, service, and support capabilities, partnering with our customers to deliver the results they require for life.