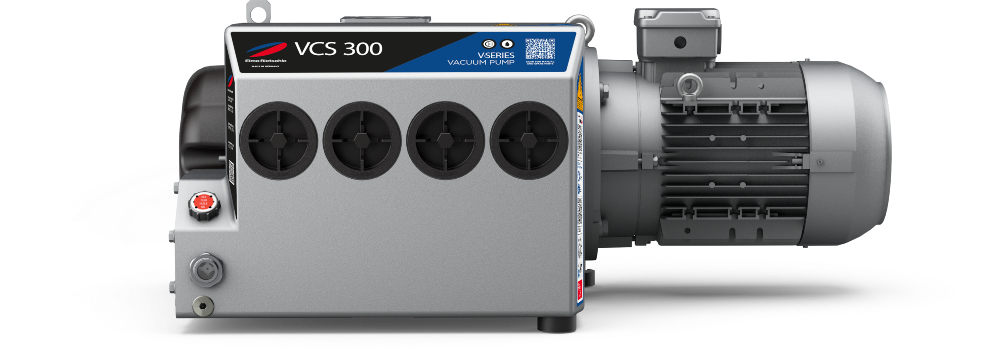

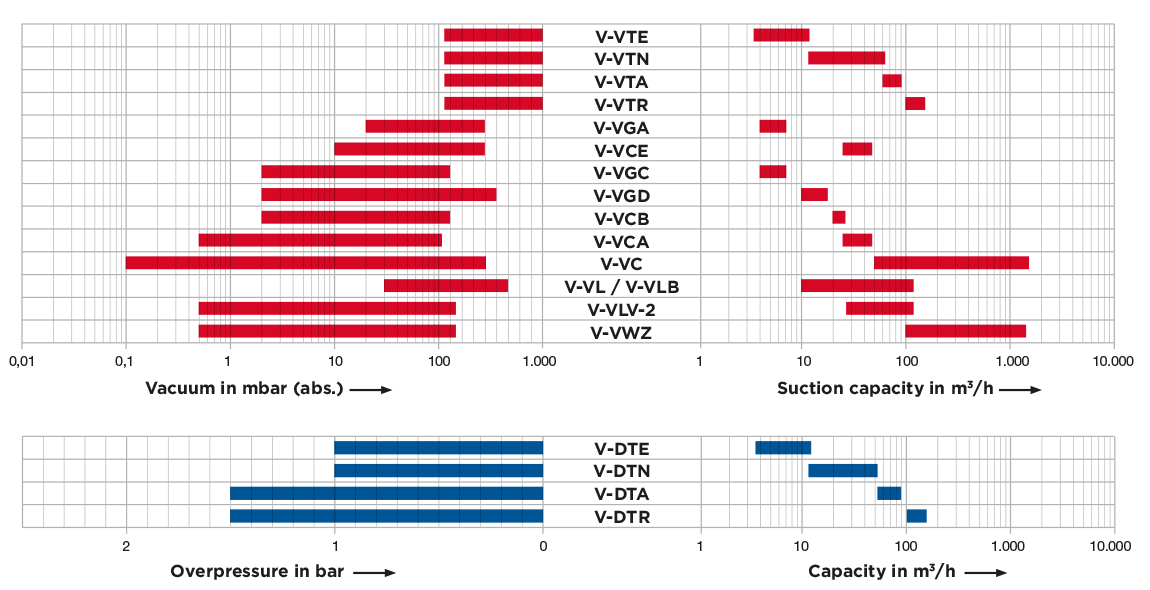

Oil Lubricated Rotary Vane Vacuum Pumps

- V-VGD, V-VCB, V-VCA, V-VCE and V-VC

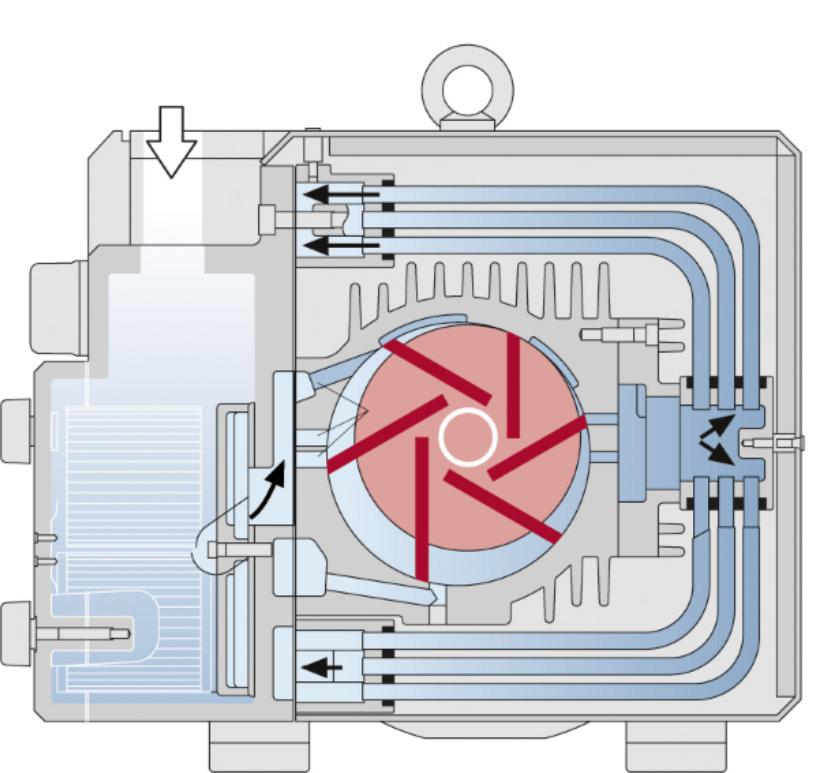

Our oil lubricated rotary vane vacuum pumps are used in a wide variety of industrial applications. We offer the largest range of oil flooded vacuum pumps for industrial vacuum operation.

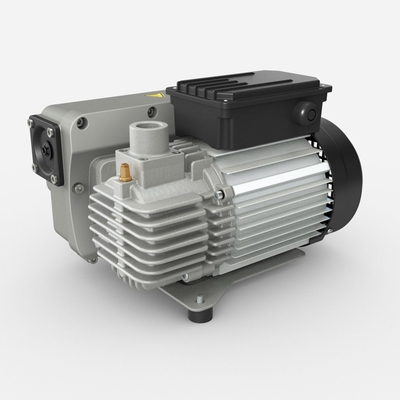

Dry running rotary vane vacuum pumps, compressors and pressure-vacuum pumps

Compact V-VTE vacuum pumps and V-DTE compressors are each available in four sizes. Low noise and reliability make this series an ideal choice for many OEM applications.

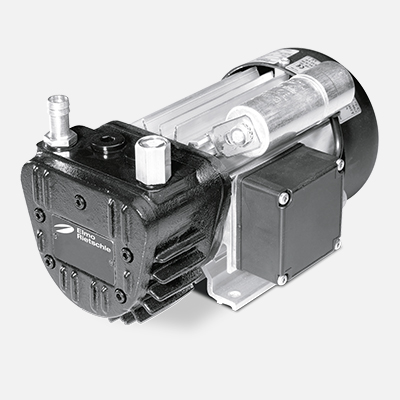

Our medium size dry pumps are available in vacuum (V-VTN), pressure (V-DTN) and combination models (V-KTN). Design features of these include maximized cooling air pathways, heat resistant materials, sound reduction covers and relief valves.

The next largest group of dry rotary vane pumps also offers all operation types – vacuum (V-VTA), pressure (V-DTA) and combination models (V-KTA). Developed as continuous duty pumps for printing and paper handling machines, this series is now used widely in many industrial applications.

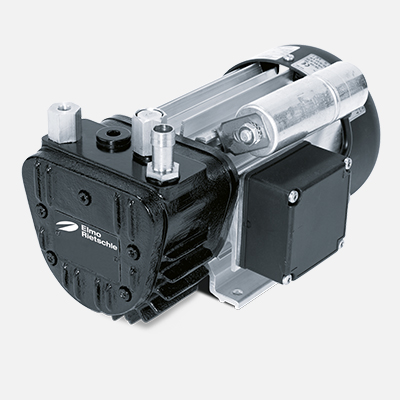

A new range of rotary vane pumps is available as vacuum (V-VTR), compressor (V-DTR) and as combined pressure-vacuum version (V-KTR). The benefits of the new range are visible at a glance: maintenance and control panel are placed on one side only for easy access to filters and valves. Additional features include heat reduction through large cooling air pathways and vents. Design features such as the solid ribs, optimised cooling air circulation, thermal separation of suction and compression chambers within the filter housing, as well as a minimum number of connected heat transferring parts reduce machine temperatures.

Global (EN)

Global (EN)