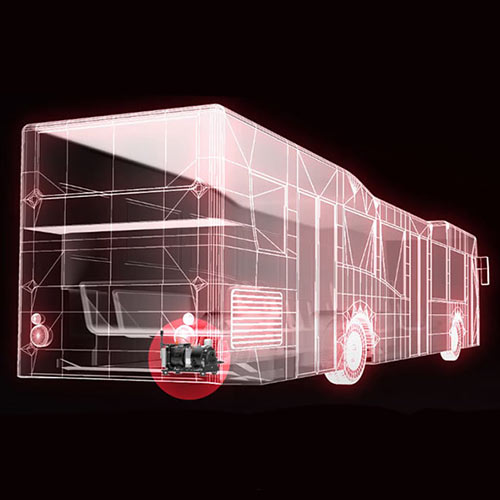

It was at this point Gardner Denver Transport was approached. ARCC came across the company’s earlier work with Wrightbus in 2012, which saw Hydrovane compressors installed on 1000 new hybrid-powered London Routemaster buses. The Australian company wanted to know more about the project and how the final package was developed to support all on-board pneumatic functions.

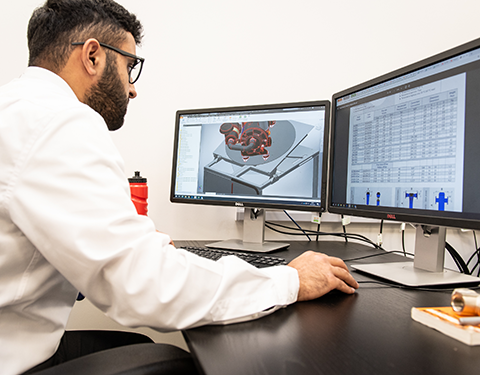

After an initial conversation, ARCC then visited Gardner Denver’s Redditch facility to get a better understanding of how the company could support the rollout of its own electric vehicles. David Evans at ARCC met with Gardner Denver Transport’s team of e-mobility experts who recommended the TA02 – the same model of compressor that was installed with great success across the New Bus for London project.

Dion Pearson, Sales Manager for Gardner Denver Transport in Australia, explains how this project developed: “It was clear that ARCC needed a committed partner to achieve its aims. Breaking into an established market is difficult at the best of times, particularly when introducing new or unproven technology, so the company needed a partner who could assure excellence and ongoing support.”

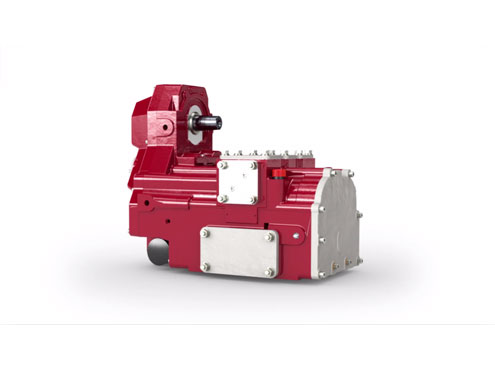

The work was such a success that ARCC then appointed Gardner Denver to work on its latest bus prototype powered by hydrogen fuel. Needing a lighter, more robust compressor, Gardner Denver offered a new package using the TX02. This model is ideally matched to electric drives, with its simple integration, lightweight design and quiet operation. The TX02 is also vibration-free, meaning passengers and pedestrians are guaranteed a comfortable journey – a key consideration for operators in this market.

As Pearson adds, the ARCC project underlines how Gardner Denver Transport is able to use its centralised expertise in the UK alongside local service centres: “We’ve made good use of our international network and regional presence here in Australia to deliver a quick and effective cross-border solution for the customer. Our team coordinated with HQ in the UK and, despite the time difference, were able to keep the project well on time and within budget.”

Global (ZH)

Global (ZH)