Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

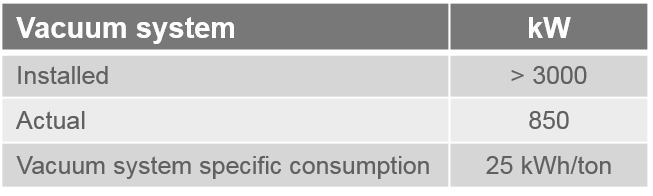

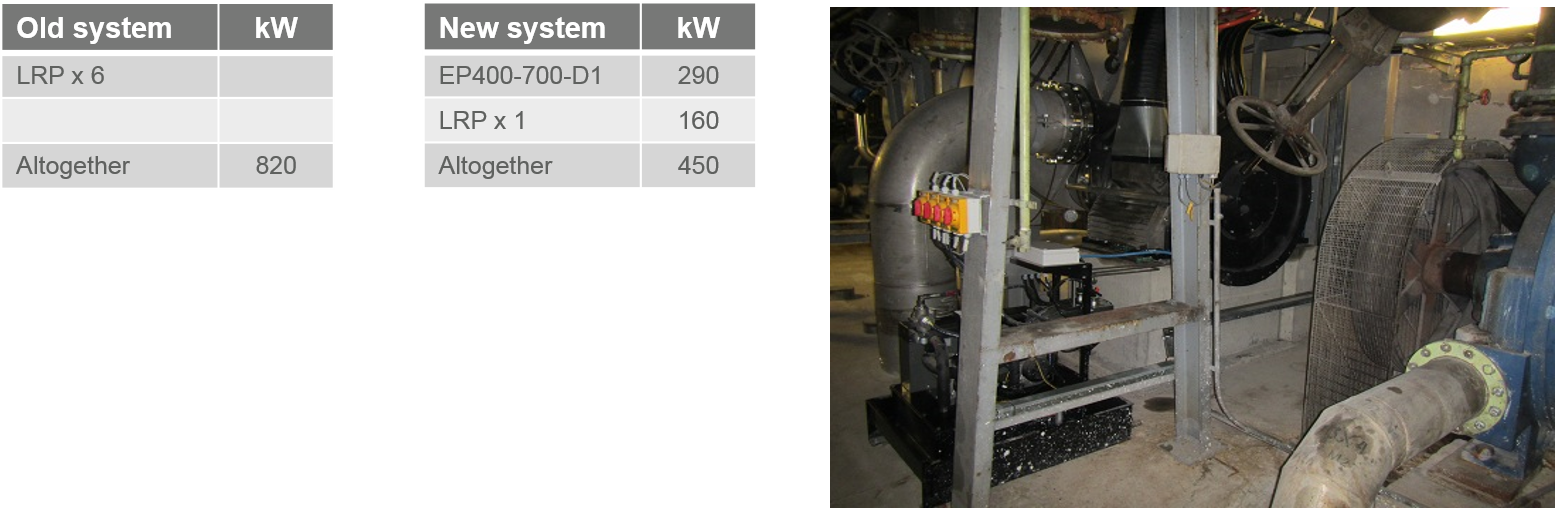

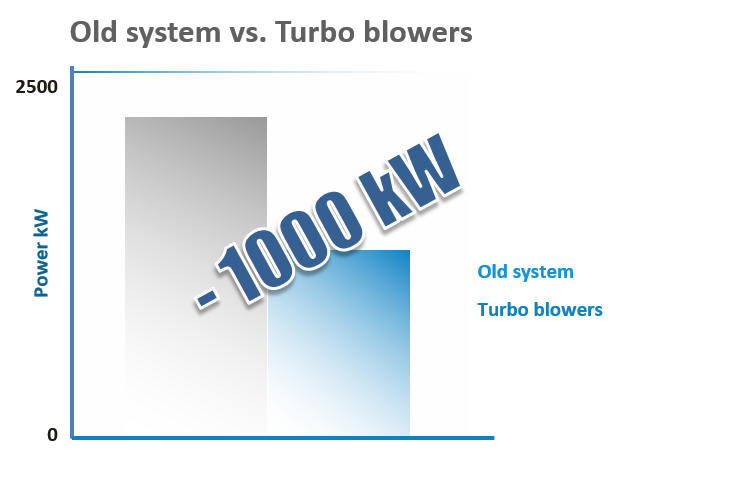

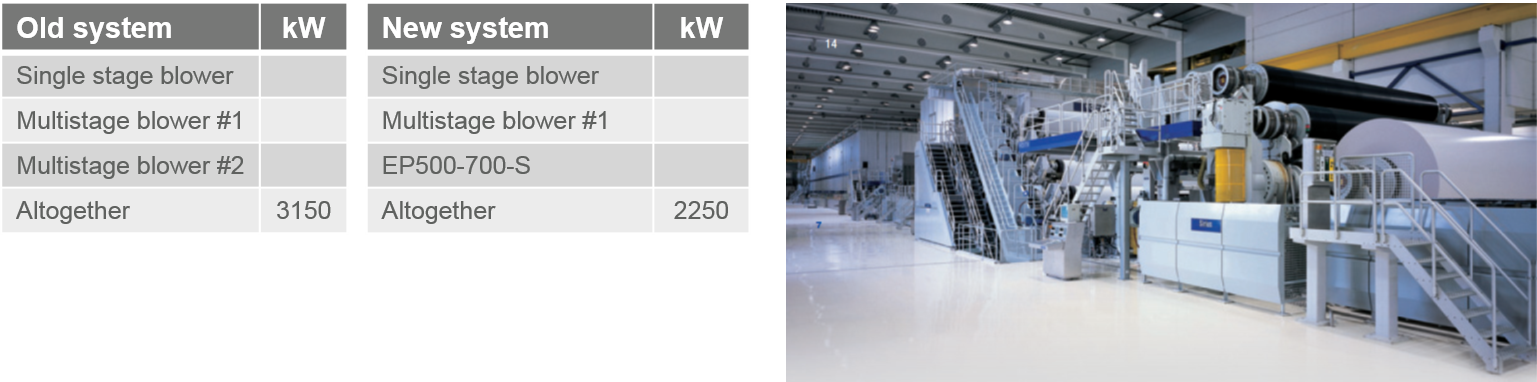

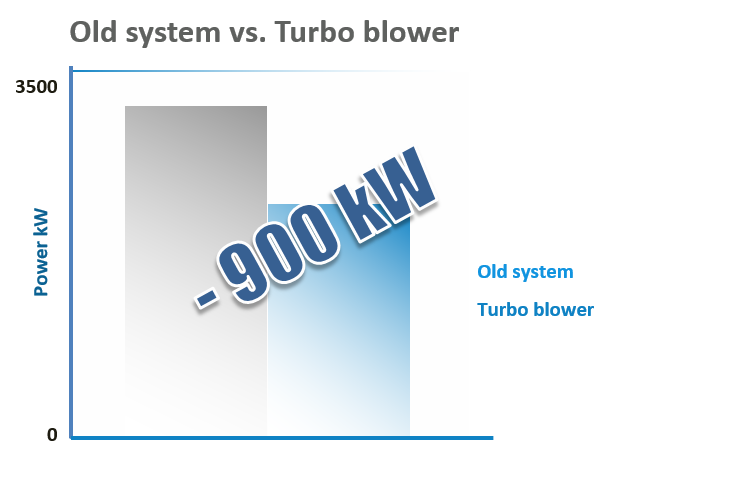

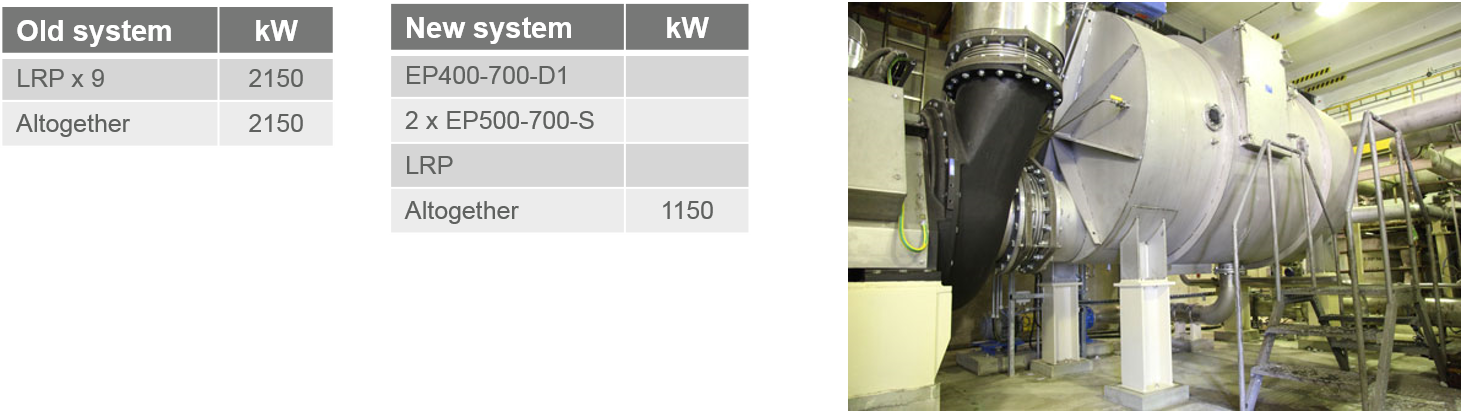

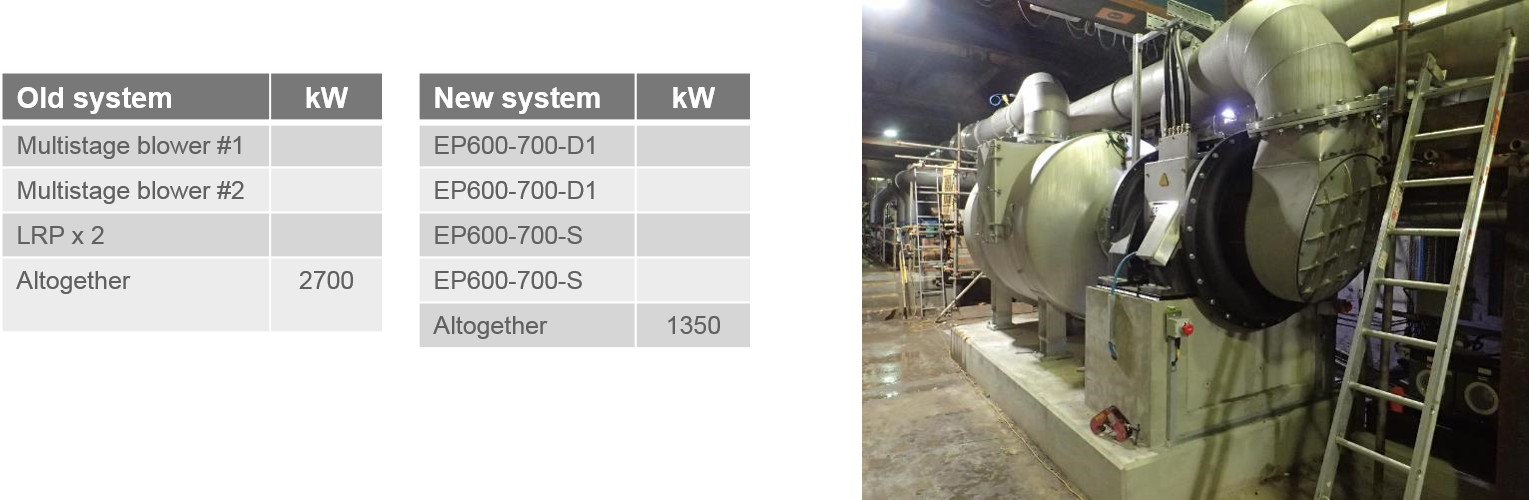

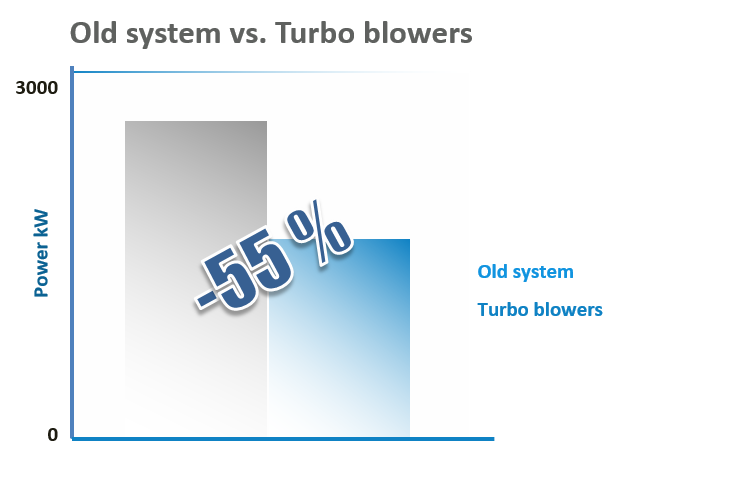

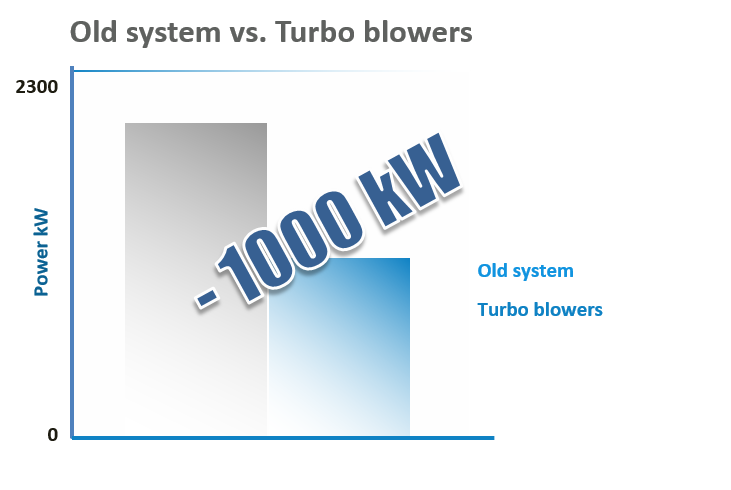

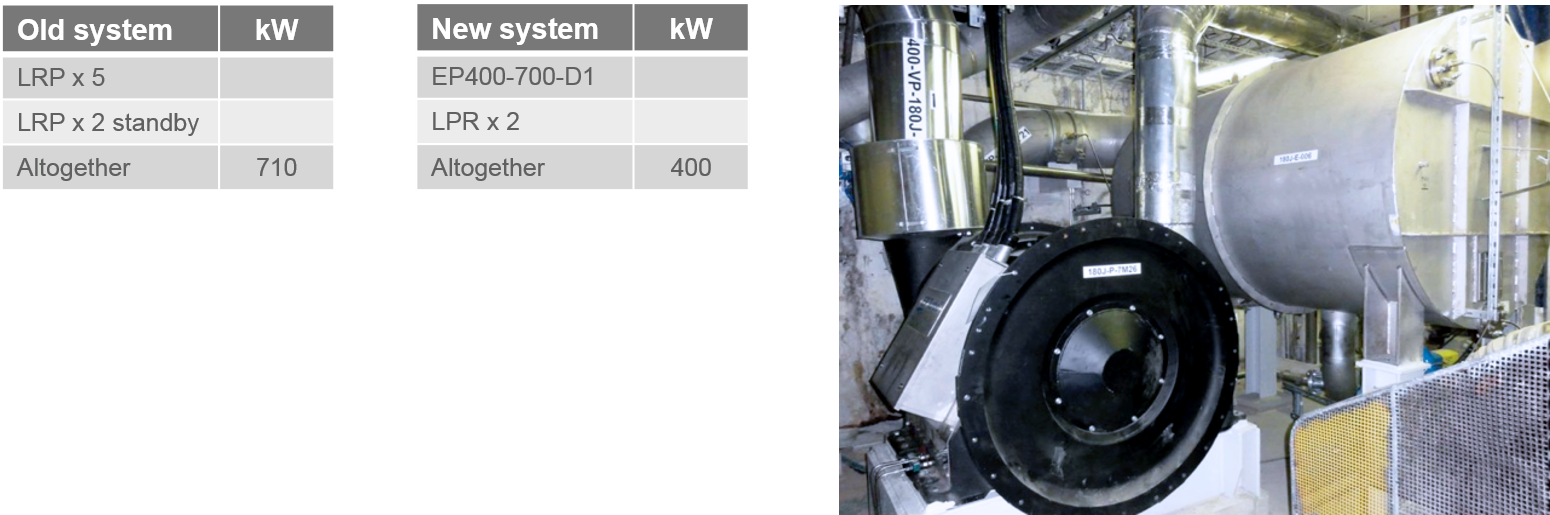

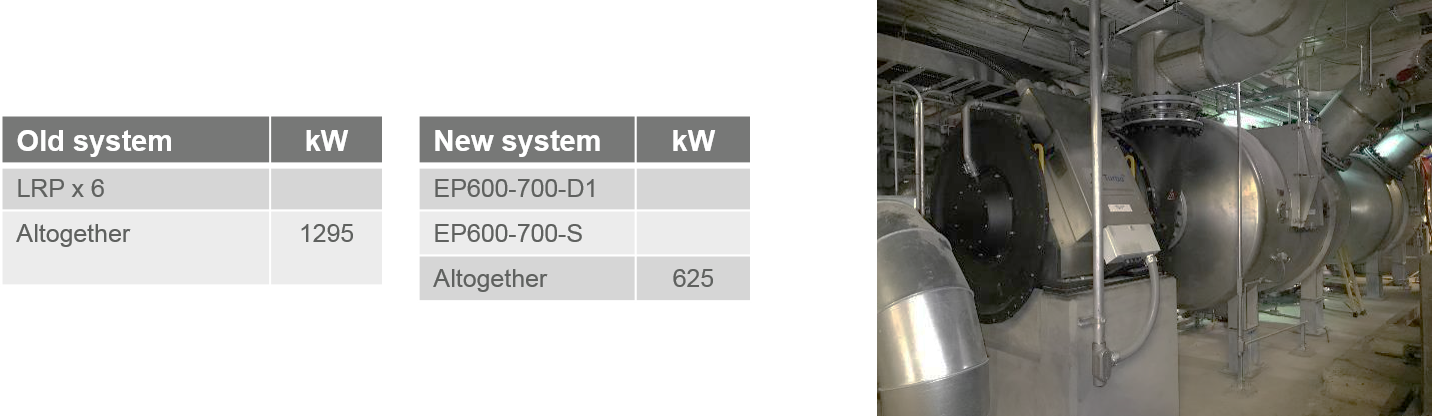

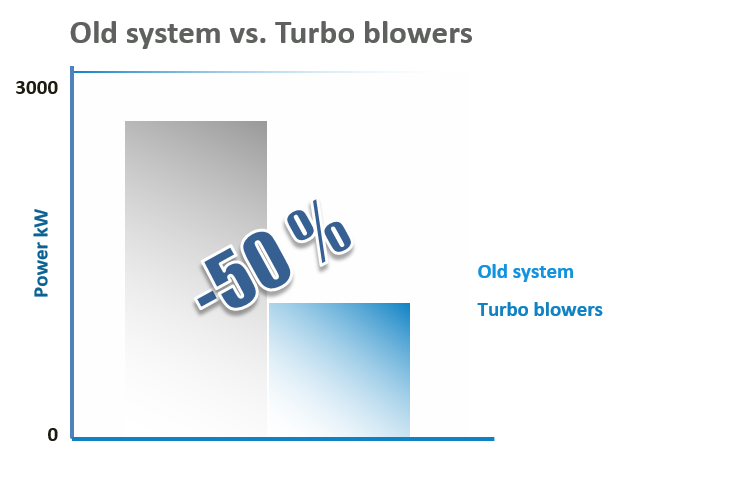

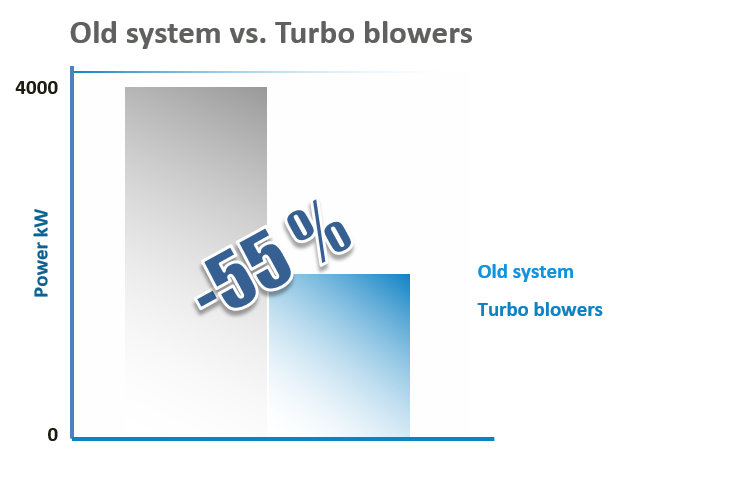

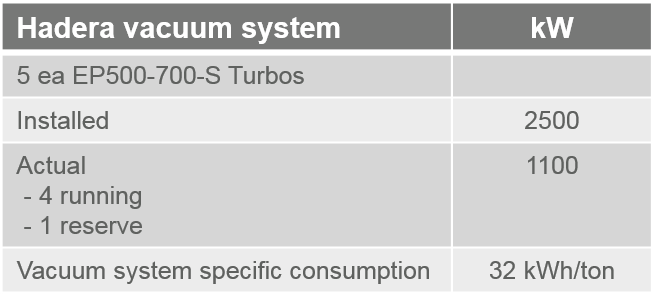

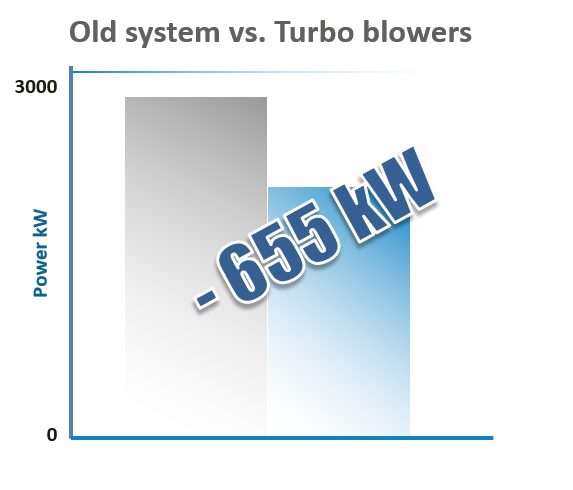

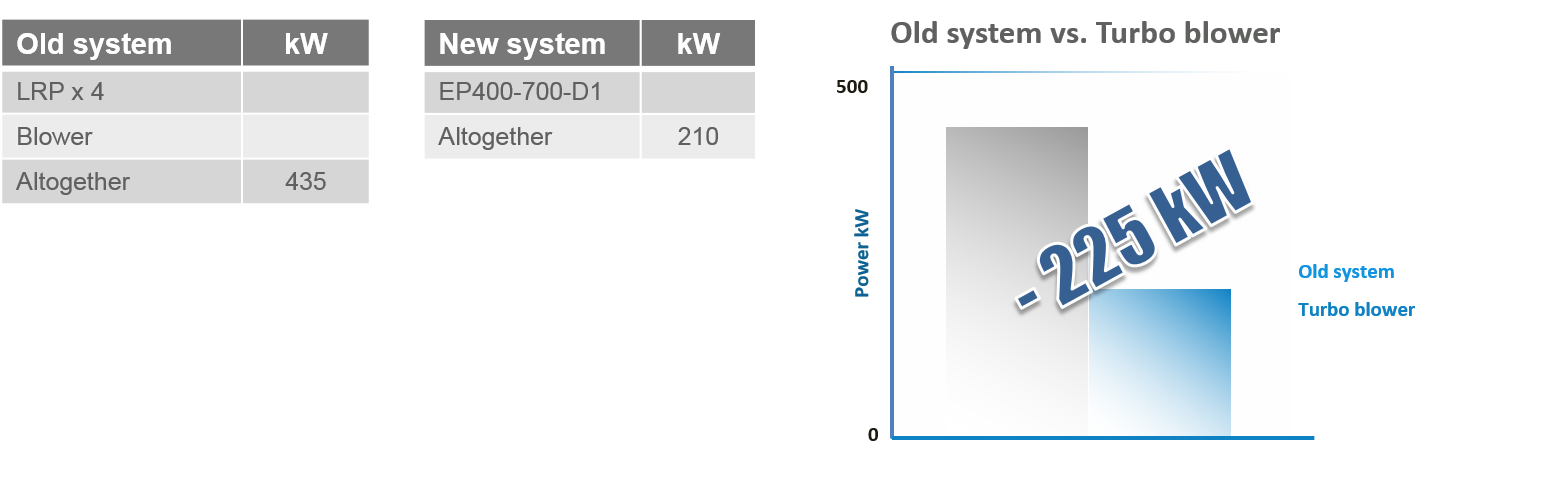

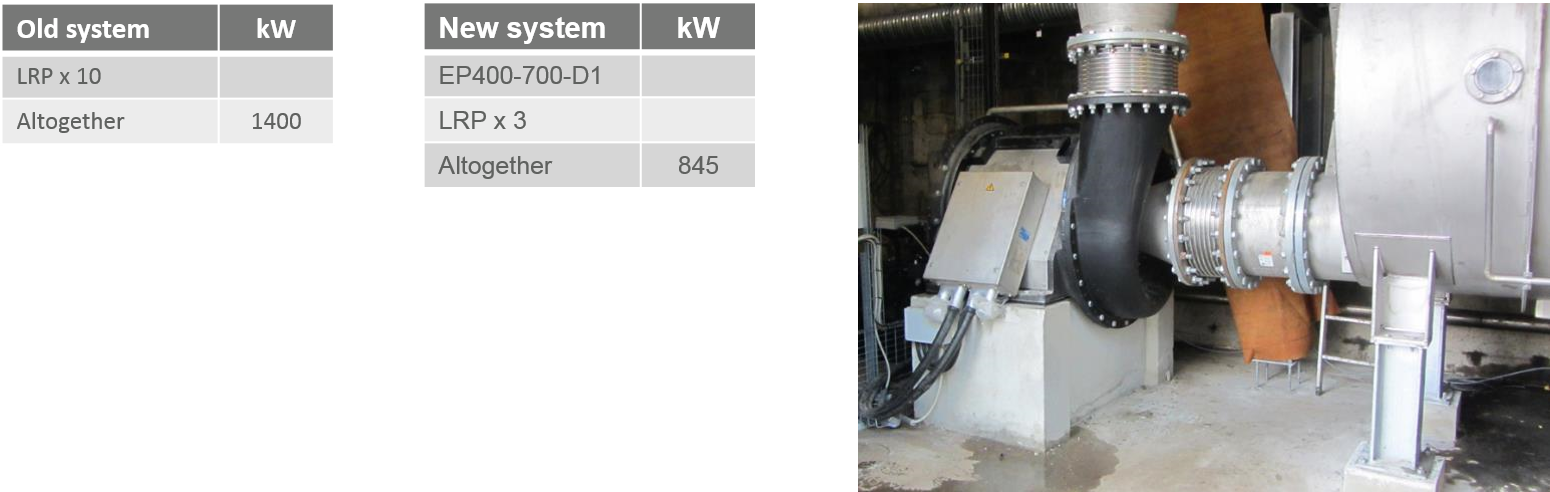

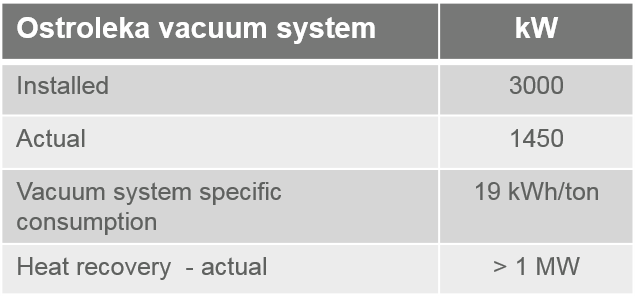

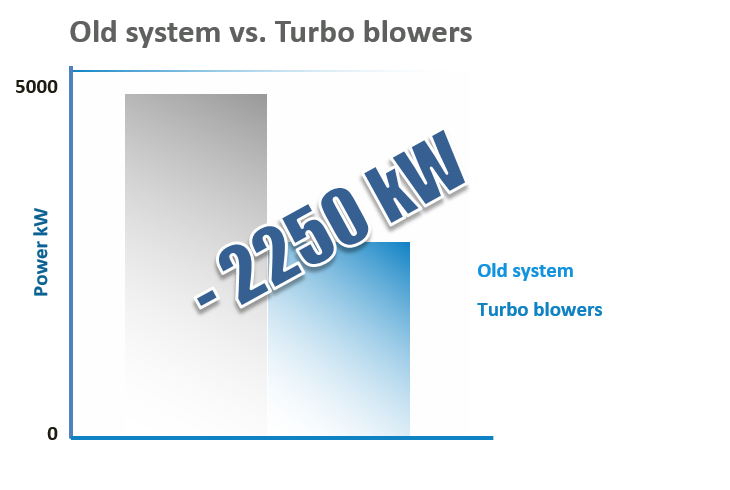

Original (since 2004) vacuum system was oversized but it was not possible to just stop any of the existing blowers.

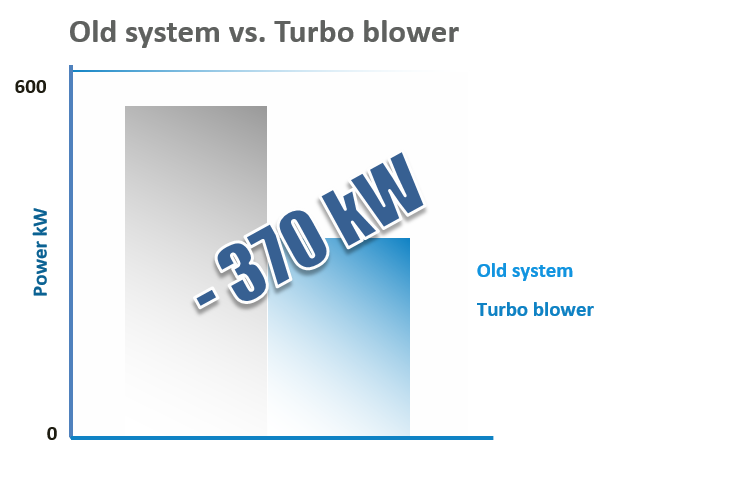

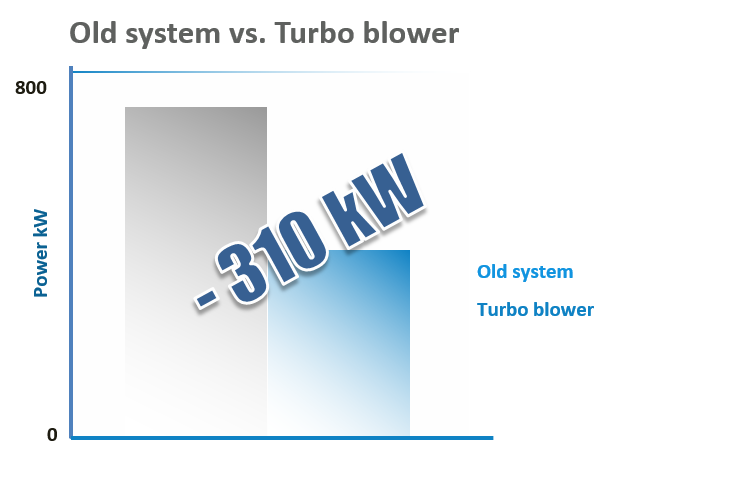

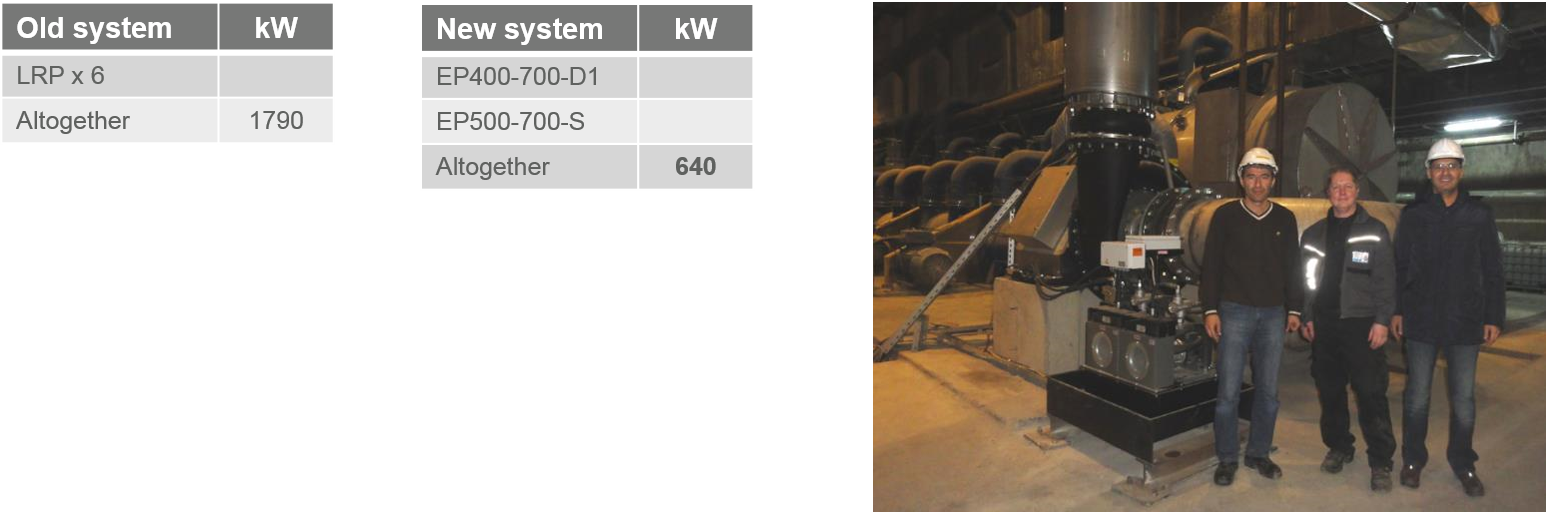

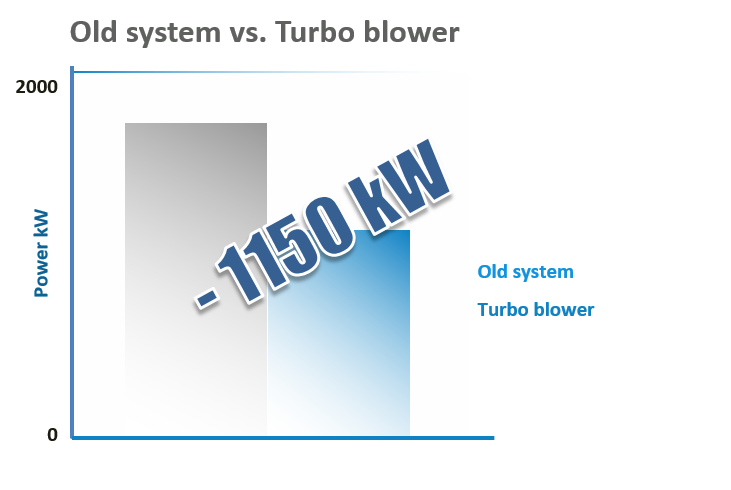

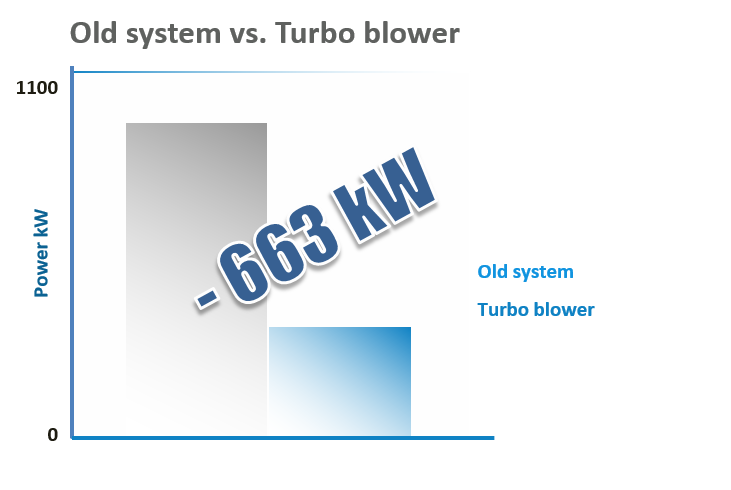

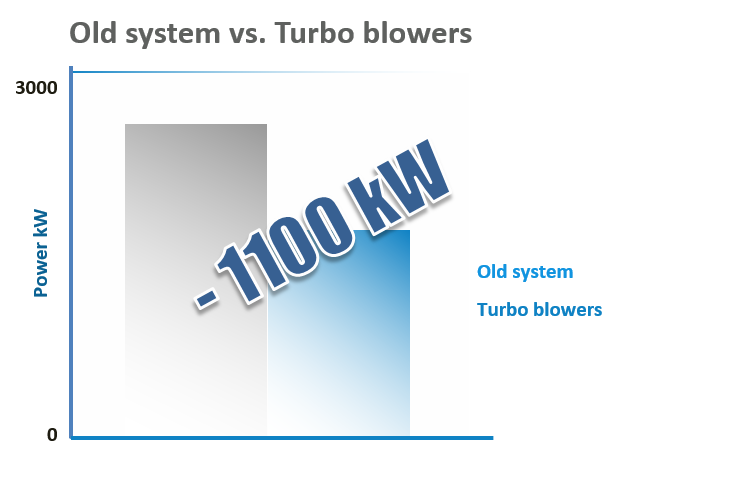

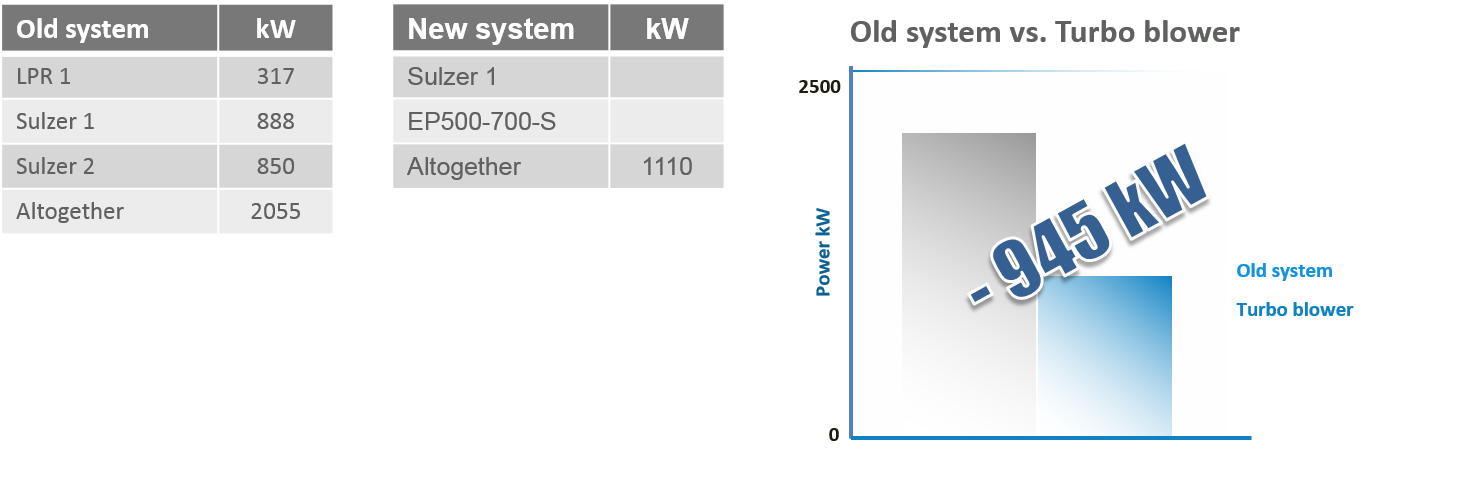

One EP500 Turbo replaced 1,3 MW multistage unit.

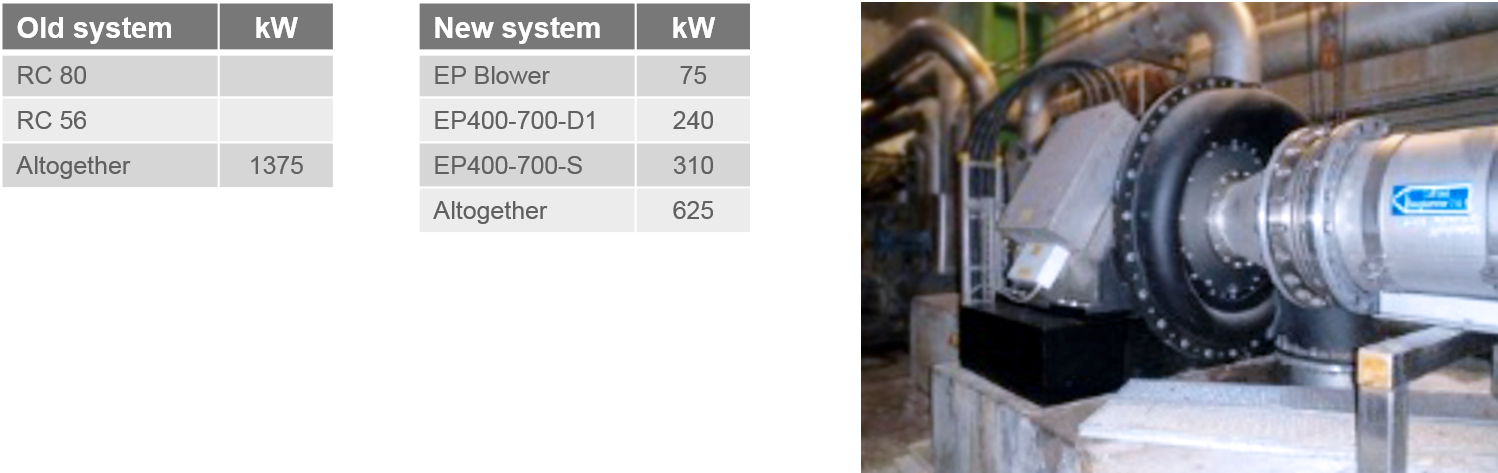

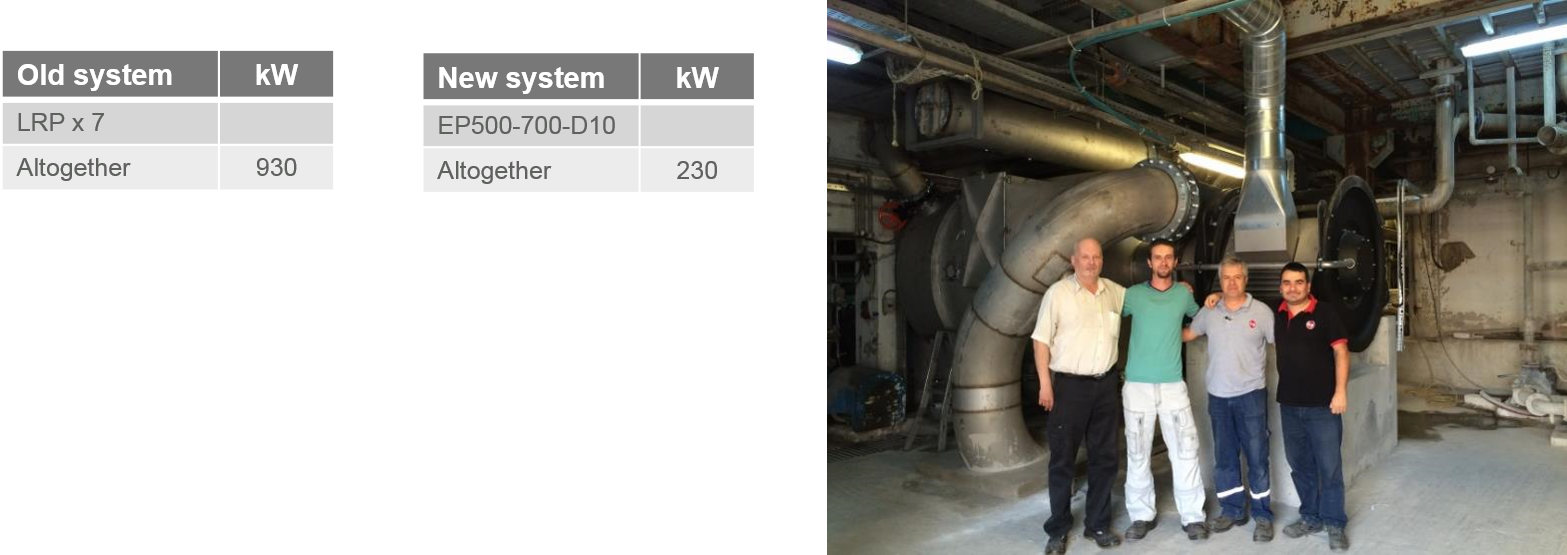

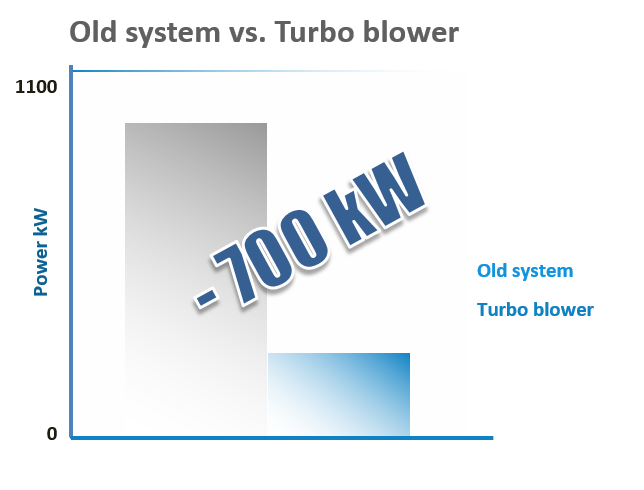

Vacuum system was studied in April 2012 and calculations showed significant energy saving potential. Vacuum system includes three (3) single stage blowers

“New vacuum system allows a more reliable and smoother runnability than the old system. Possibility to install it on existing foundation and the flexibility of the Turbos thanks to variable speed allows the system to adapt in lots of situation and a wide functioning area. Energy saving already made is quite significant and future optimization is still planned.

Doctor optimization has been a key to improve press section dewatering and improve dryness after press section for speed development. Being as well a vacuum system expert and a doctoring expert is really a runtech strength. This has allowed to see the project as a whole package and to really optimize the system.”

Sebastien Finel, Production Manager PM3.

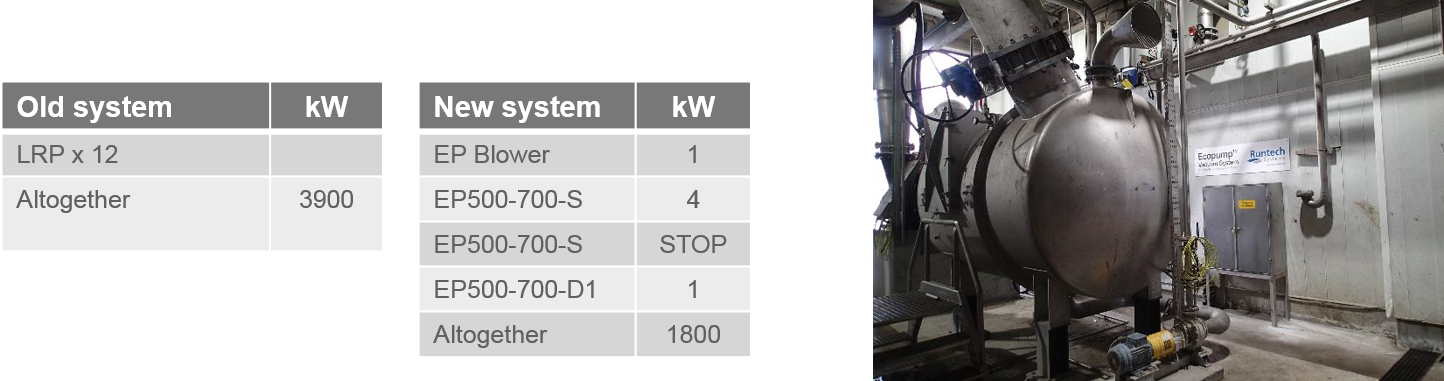

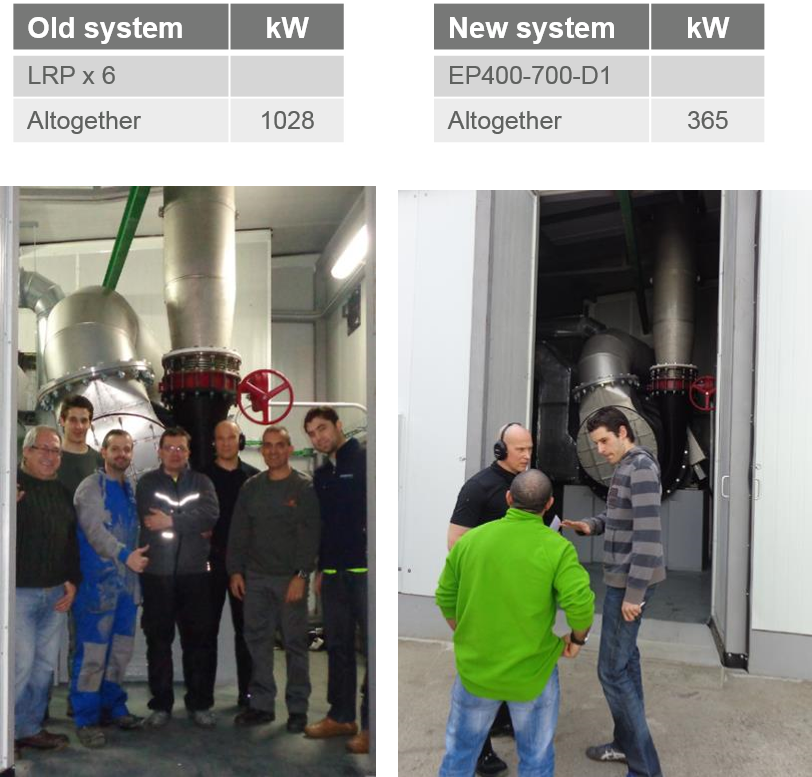

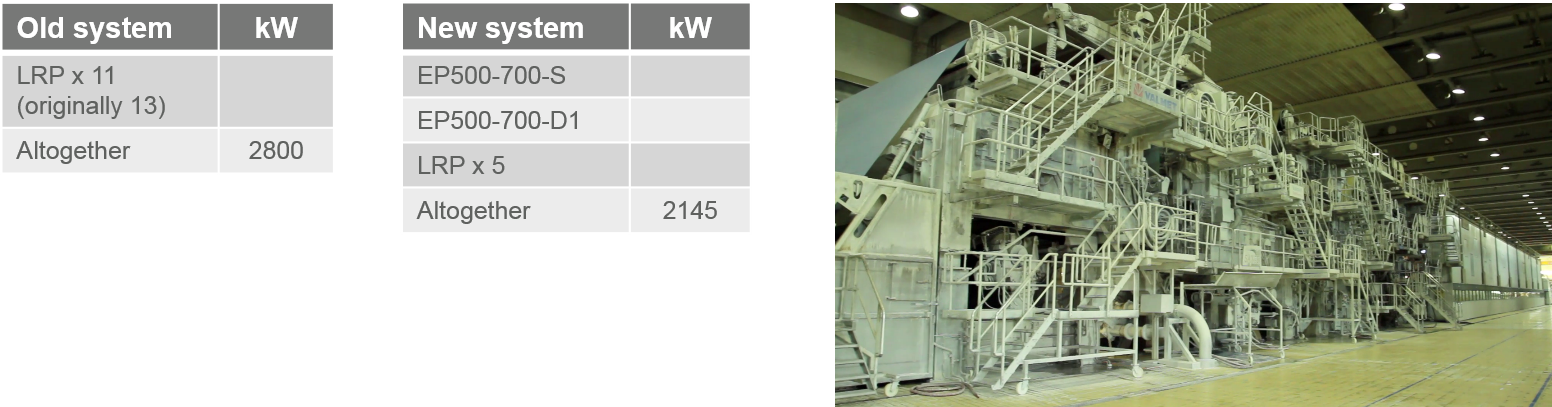

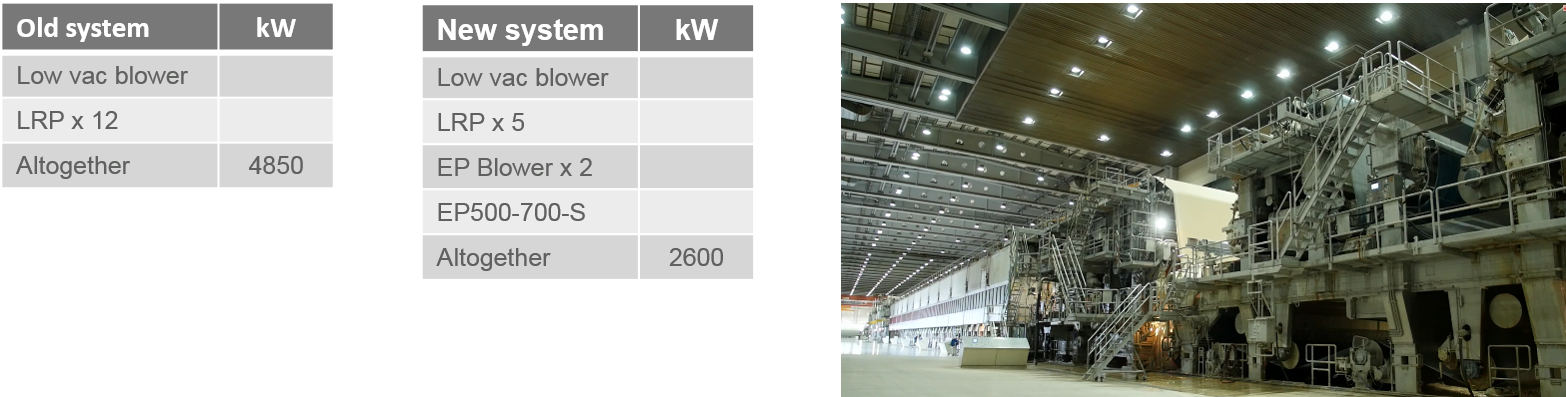

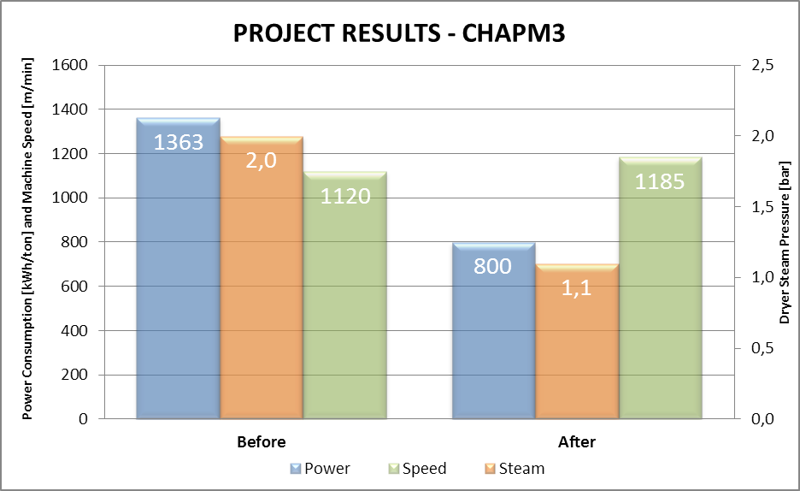

Chapelle PM3 vacuum system was fully rebuilt 2012 together with wire and press section dewatering optimization. Chapelle PM3 is newsprint machine (wire width 6,0 meters) with conventional tri-nip press and machine speed up to 1250 m/min.