FAQs About Dry Vacuum Pumps

Q: What is a dry vacuum pump?

A: A dry vacuum pump is a type of pump that operates without the need for liquids such as water or oil in the pumping chamber. This design feature ensures that the pump provides a clean, oil-free vacuum, making it ideal for applications where contamination must be avoided. Dry vacuum pumps often use two non-contacting, rotors to trap and transport gas from the inlet to the exhaust.

Q: Can vacuum pumps run dry?

A: While traditional vacuum pumps may require lubrication or fluid in the pumping mechanism to operate, dry vacuum pumps are specifically designed to run dry, without the need for any liquid in the process. This allows for a clean operation and reduces the risk of contaminating the process or environment. While the pumps do require lubricants for the bearings and sometimes a fluid to cool the pump, neither are able to come in contact with the process gas.

Q: Where are dry vacuum pumps used?

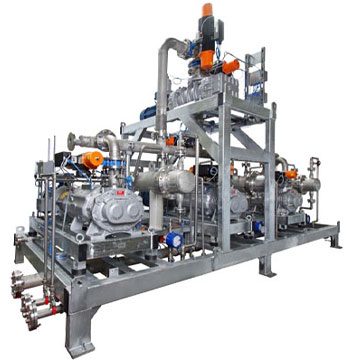

A: Dry vacuum pumps are versatile and are used in various industrial settings, including chemical, pharmaceutical, industrial, and petrochemical applications. They are particularly useful in processes such as degassing, vacuum metallurgy, vapor recovery, and central vacuum systems where a clean and oil-free vacuum is crucial.

Q: What are the benefits of a dry vacuum pump?

A: Dry vacuum pumps offer numerous advantages over traditional pumps that use fluids. Liquid sealed pumps typically have a waste stream of liquid that comes at a cost and usually requires treatment before disposal. As the pumps do not need to drive a motive fluid, they require less electrical power and operate more efficiently. Some benfits in addition to the reduced environmental impact include lower installation and operating costs, easier maintenance, and a longer service life. They also provide a flexible vacuum solution with the ability to handle corrosives, organics, inorganics, and solvents safely and reliably.

Downloads For Dry Vacuum Pumps & Systems

USA (EN)

USA (EN)