A Complete Project With Tight Deadlines

Project selection was only one part of the challenge for the Nash team. Crude distillation and vapor recovery are essential functions in an oil refinery. To avoid downtime or a partial system shut down, which would impact capacity, BPCL wanted to complete the CDU/VDU project during the planned refinery shut down period (March 2017). This provided the team with a short 5 month delivery period, and a requirement to complete installation and commissioning during the 21-day refinery shut down.

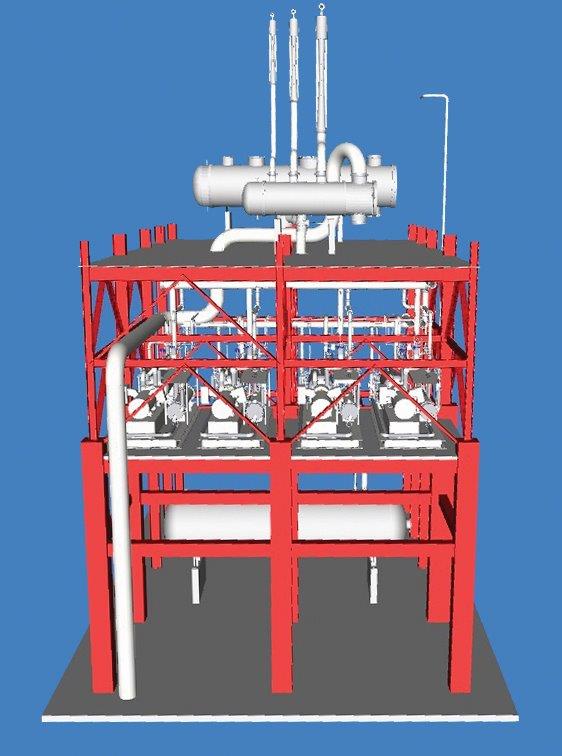

Working across departments and countries, the Nash team successfully completed the engineering, sourcing, package building, testing (utilizing BCPL’s testing specifications), and shipped the material within the agreed on 5-month period. This was all possible thanks to a concentrated effort by Gardner Denver Nash team members in China, Germany, the United States, and India. The result was a complex hybrid vacuum system consisting of ejectors from the United States, motors from Germany, and liquid Ring Vacuum packages from China, with all construction and coordination handled by the team in India, who remained on site to supervise and ensure the project was completed on time.

There was also excellent support & coordination from the BPCL team to complete the project documentation, resolving the issues/challenges raised during the execution time and for the site activities.

Global (EN)

Global (EN)