Waterjetting pumps are only as effective as the components they are paired with. GD Energy Products Multi-Blasters deliver a packaged assembly of integral components customized to meet your unique application and horsepower requirements.

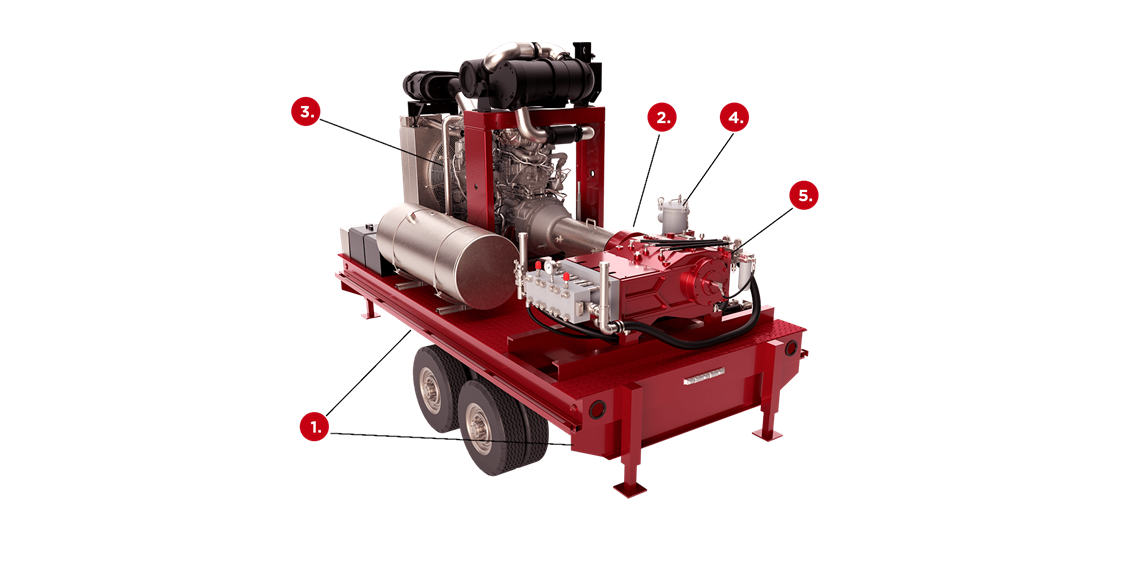

GD Energy Products Multi-Blasters are comprised of our rugged triplex positive displacement pumps packaged with integrated filters, discharge plumbing, a power unit and drive train. Package options include electric motors or diesel engines, skid or trailer mounting, belt or direct drive, and optional transmission or PTO clutch. Trailer mounted units can be fabricated in so that a CDL is not required.

GD Energy Products waterjetting units are used for hydrostatic testing, concrete demolition, air-preheater cleaning, runway cleaning, vessel cleaning, paint overspray removal and more. With decades of experience in packaging waterblasting units, we have come to anticipate the needs of customers from any market requiring waterblasting equipment. GD Energy Products has seen every configuration waterblasting unit, from demanding offshore environments to caustic environmentally challenging requirements including the petrochemical sector, and we can customize a unit to meet your specific needs.