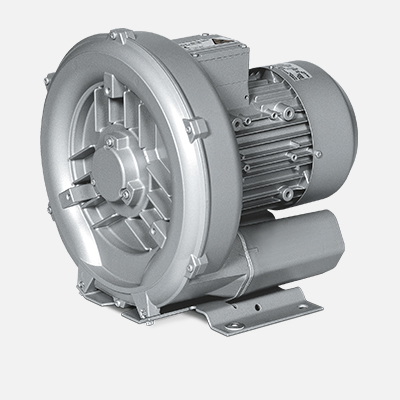

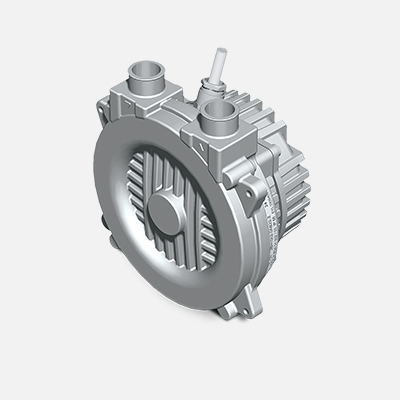

The smallest side channel blower on the market - G-BH100

G-BH100 blowers are the smallest side channel blowers available on the market, with a height and width of approx. 125 mm and a depth of approx. 60 mm.

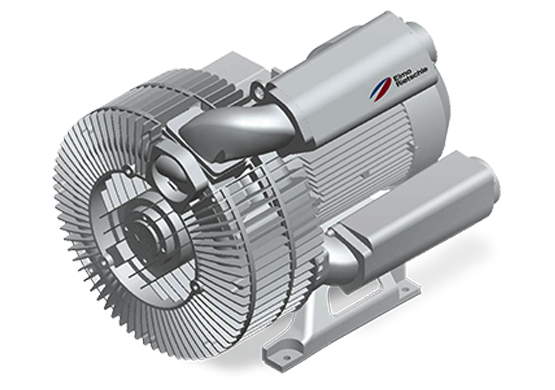

Classics with innovative technology - G-BH1

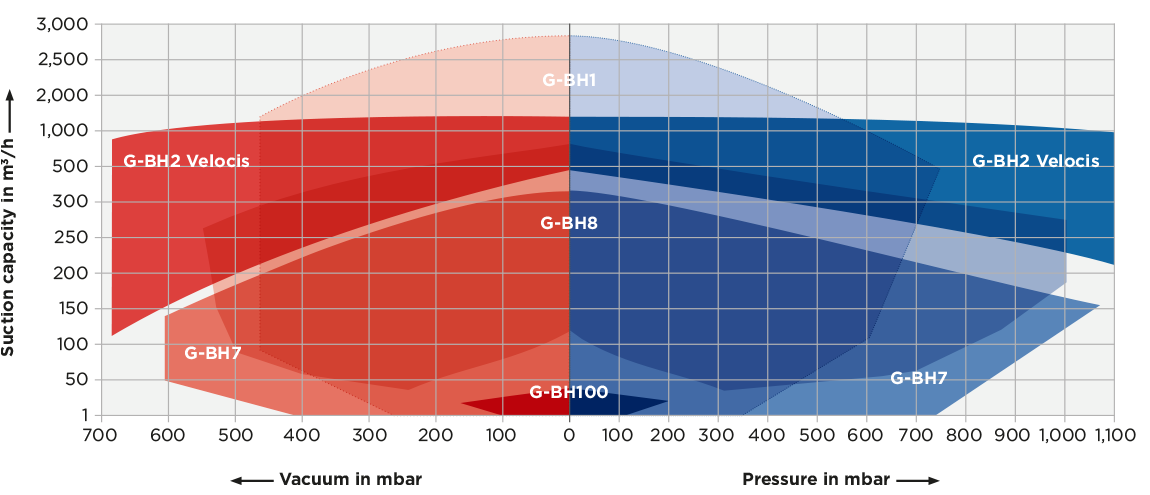

With their high inlet volume flow up to 2,500 m³/h and a differential pressure of up to 780 mbar, our low noise G-BH1 side channel blowers have earned their reputation. They are reliable, low maintenance and durable. They deliver 20,000 operating hours without fail and are virtually maintenance free. IE2 G-BH1 with IE2 motors available on request.

The side channel revolution - G-BH2 VELOCIS

Volume flow up to 850 m³/h and differential pressure up to 1,100 mbar. With its significantly expanded range of performance, the side channel technology can now be used in completely new applications. IE2 The entire G-BH2 VELOCIS range features IE2 motors

Advantages at a glance

• Wear free

• Low operating and energy costs

• Extremely smooth running

• Very low noise level as a result of acoustic engineering

• Dust and fluff resistant

• Pulsation free

• 50/60 Hz voltage range motors

• Operation with frequency converter with 87 Hz

• 40,000 operating hours

Unsurpassed at highest differential pressure - G-BH7

Our G-BH7 side channel blowers can create pressure differences of up to 1,000 mbar – more than any other gas ring compressor! So far, the systems used to reach these differential pressure ranges were much louder and larger – or subject to wear.

Now the advantages of wear free operation coupled with a low noise level can also be used in the most demanding applications. The G-BH7 vacuum pumps and compressors can work up to 20,000 hours without maintenance down time. These specialist machines have proven their reliability under the harshest of conditions.

IE2 G-BH7 with IE3 motors on request

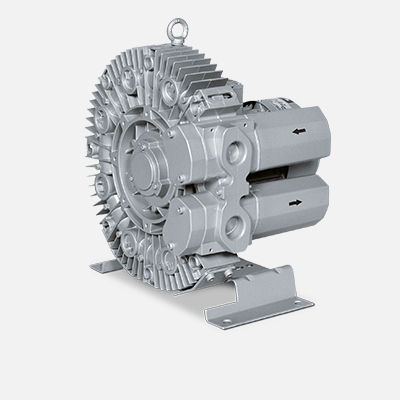

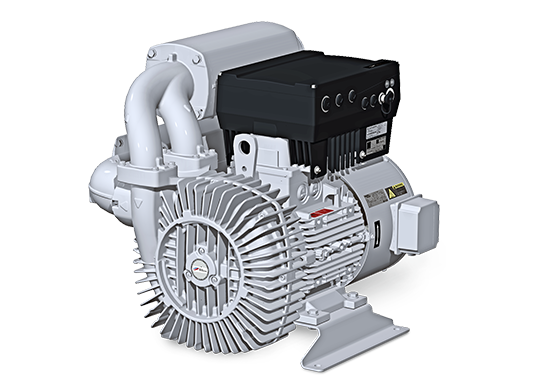

Half the size, twice the power

G-BH8

Side channel blower with maximum power/weight ratio and extremely flexible power control (-550 … +720 mbar)

Technical Highlights

• Lower energy consumption thanks to higher pump efficiency

• Flexible speed drive

• Noise emission reduced by half

• Pulsation free compression

• Virtually maintenance free

IE3 The entire G-BH8 range features IE3 motors

Suitable for use Worldwide

The G-Series side channel blowers the ideal solution for worldwide use; they can be used without modifications or tests in Europe, Asia and America. This includes voltage range motors for 50 and 60 Hz in protection class IP 55 (insulation class F) and are UL 1450 and CAN/CSA C22.2 No. 68-09 approved.

Global (EN)

Global (EN)