Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

Since 1986, when Nash acquired the Kinema Corporation, we have designed and manufactured ejector/liquid ring pump hybrid systems that combine ejectors with liquid ring and other vacuum technologies. Our design offers improved efficiency and reduces greenhouse gas emissions and operating costs. NASH ejectors & hybrid vacuum systems are backed by a complete system warranty and our global engineering, service, and technical support team.

Review our product portfolio and discover the NASH technology best suited for your application-specific needs.

Nash manufactures the most efficient steam jet ejectors, recognized worldwide for delivering reliable performance and lower emissions. Our ejectors have the ability to handle large volumes at very high vacuum levels and can be optimized in a variety of ways based on initial cost, payback period, or utility limitations.

Additional efficiency benefits can come from pairing ejectors with liquid ring vacuum pumps to create an ENER-JET™ Hybrid Vacuum System.

Our experienced team of application engineers can optimize a hybrid system specific to your process, application, and technology requirements to deliver maximum efficiency and performance benefits.

Our NASH ENER-JET™ Steam Ejector Hybrid Vacuum System combines the stability of our liquid ring pumps with the high vacuum capabilities of our steam jet ejectors resulting in a hybrid vacuum system that reduces greenhouse gas emissions and operating costs while improving system stability. Hybrid systems can be used in any industry or application where deep vacuum is required like chemical, electrical power, oil & gas, and pharmaceutical industries.

NASH Air Ejector Hybrid Vacuum Systems combine the low maintenance technology of air jets with the proven reliability of liquid ring vacuum pumps to deliver deep vacuum for low flow applications such as deaeration, offshore platforms, and condenser exhausting where steam is not available or undesirable.

Our air ejectors operate on proven jet pump principles using atmospheric air as motive medium. Pressurized air or other non-condensable gases can also be used to make the system more efficient by using a smaller vacuum pump.

These systems are recommended when a liquid ring vacuum pump cannot achieve the vacuum level desired due to vapor pressure limitations of ring liquid technology. The air ejector increases the vacuum level the pump can reach with reduced capacity.

NASH Booster Hybrid Vacuum Systems combine liquid ring technology with vacuum boosters, and sometimes air jet ejectors, to deliver efficient and economical vacuum solutions. Engineered to work with any vacuum system design for reactor vacuum and solvent dewaxing applications.

When vacuum levels cannot be met by a liquid ring vacuum pump alone, our extensive expertise allows us to optimize a multistage booster/liquid ring pump hybrid system that delivers the vacuum and flow you require, with the reliable and low maintenance operation you expect from Nash. Properly designed booster systems deliver reliable performance with a long operating life.

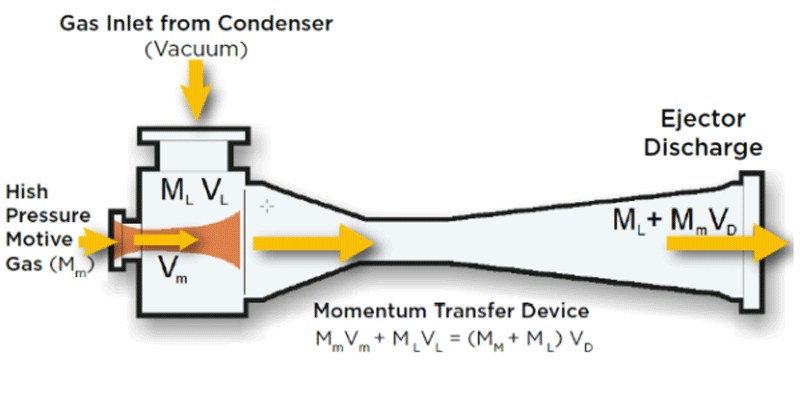

Steam ejectors use steam or gas instead of moving parts to compress a gas. In a jet or ejector, a relatively high-pressure gas, like steam or air, expands through a nozzle. The steam or air converts that pressure or potential energy to velocity or kinetic energy. The jet of high-velocity steam or gas entrains the gas to be evacuated or pumped in the suction of the ejector. The resulting mixture enters the diffuser where velocity energy is converted to pressure at the ejector discharge.

Ejectors that use air as motive are often called air ejectors or air jets. Air is often employed on small ejectors when steam is not available. When paired with a NASH liquid ring vacuum pump, they can use the air from the room or the pump exhaust as motive air to increase the vacuum level the pump is capable of reaching. This is often used in applications such as deaeration when the vacuum system must be able to pull down to the vapor pressure of the water that is being degassed. Air jets of this type are convenient because no steam or pressurized air source is required to make it work, just the vacuum pump.

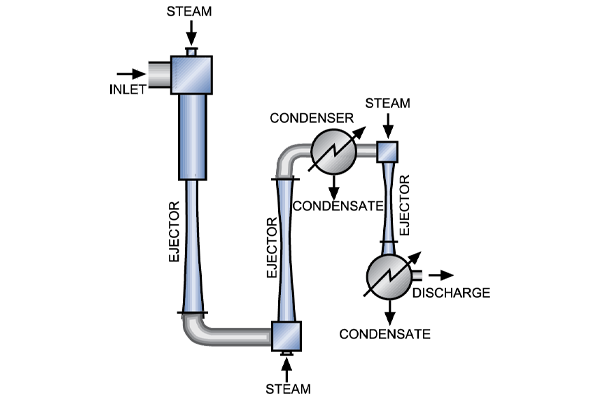

Steam ejectors can also be combined with liquid ring vacuum pumps to create a hybrid capable of deep vacuum that ejectors can deliver but with lower energy use. Nash is globally recognized for assembling the most efficient steam jet and air ejectors and ejector vacuum systems. Application engineers ensure maximum efficiency and performance benefits while optimizing a hybrid system customized to processes, applications, and technology requirements. NASH steam jet and air ejectors minimize greenhouse gas emissions and operational efficiency while improving system stability.

Steam ejectors pass steam through an expanding nozzle. The nozzle controls the expansion of steam and converts pressure into velocity; thus, creating a vacuum to transfer gases. An ejector operates on a mass basis, not by displacing volume. Therefore, ejectors are better suited to handling gases with low molecular weights and when operating at low absolute pressures. These systems are ideally suited to high vacuum applications but are only marginally useful as compressors.

A jet of motive fluid is supersonic velocity entrains the inlet stream and raises its velocity to the speed of sound as the two flows mix. A stationary sonic shock wave forms in the throat of the diffuser, and absolute pressure rises sharply at this point. More pressure rise occurs along the discharge cone as flow slows down. The most common motive fluid is steam at 80 PSIG (6 bar abs.) to 400 PSIG (28 bar abs.). Other fluids can be used whenever there is a good reason to avoid mixing steam with the product.

Steam ejectors or steam jets, ejectors that use steam as motive gas, are by far the most popular type of ejectors. A single ejector can be designed to create as much as 27in. Hg vacuum (or about 76 mm HgA). To create a deeper vacuum, ejectors can be ‘staged’ or installed in series. Steam ejectors are favored for this because the motive gas – steam – can be condensed between some of the stages to minimize load (and motive steam) to the following stage. Steam ejectors have been used in some industries to reduce the pressure of a vessel to the point that water freezes. They can be staged to reach a suction pressure of less than 0.1 mm Hg absolute.

Steam ejectors and ejector/vacuum pump hybrids are the ideal solutions for the most demanding applications in oil & gas, chemical, electric power, food & beverage.

Nash designs, builds, and tests ejectors at its headquarters in Charleroi, PA, in compliance with HEI Standards for Steam Jet Vacuum Systems, the global standard for steam ejectors. We are also a proud member of HEI and regularly contribute to the development and improvement of industry standards.

Using more than 110 years of experience and expertise, Nash provides a wide range of liquid ring vacuum pump solutions. From pumps and compressors to customer engineered-to-order solutions, we offer a comprehensive portfolio of products that can help you solve the most complex challenges.

Backed by our NASH CERTIFIED™ Service Offering, as well as a full range of OEM parts, spare, and aftermarket services, we can act as your trusted partner; protecting your investment and providing you with total peace of mind.