Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

RunDryTM services have been successfully delivered to over 500 machines globally, including machines producing all paper and board grades, as well as tissue and pulp.

RunDryTM system has been supplied to the main papermakers globally.

Due to confidentiality reasons, the names of the mills are not shown for following cases.

How can we help you?

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness. Our main target is to bring notable energy savings and highly improved process efficiency for board, tissue and paper mills.

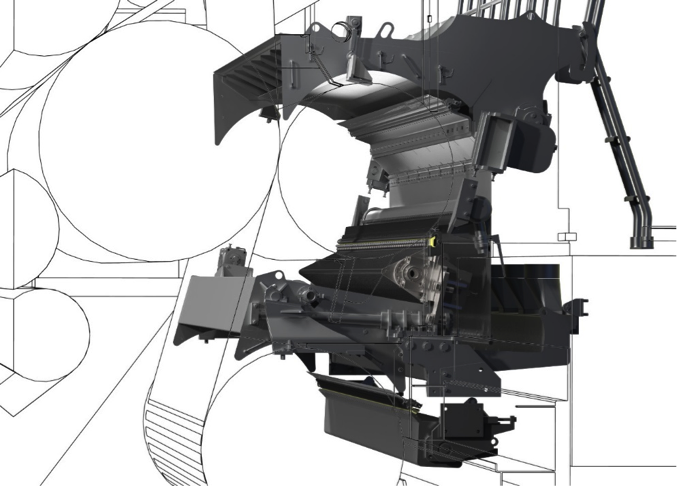

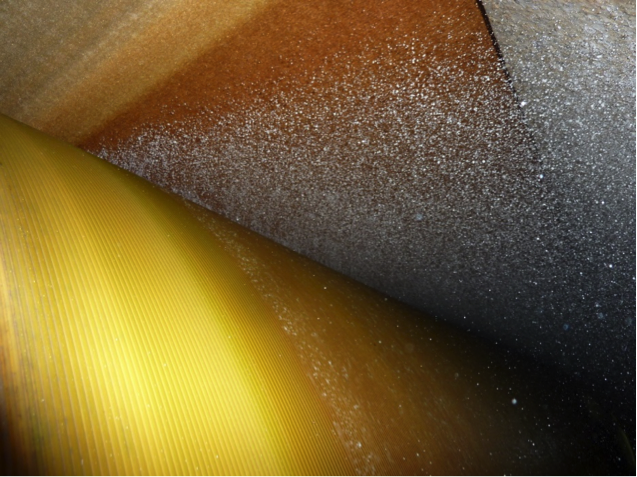

Runtech's patented solutions include energy efficient vacuum system and heat recovery optimization, runnability optimization, dewatering, doctoring and cleanliness optimization as well as ropeless tail threading, including related services, spare parts and paper machine audits and consulting.