Gardner Denver has also supplied Van der Lee with other equipment, from the Jupiter 150 to the RFL80. Over the years, Van der Lee has asked for increasingly powerful systems trusting it would speed up loading and unloading times while out on the road. Gardner Denver’s RFL range of air-cooled vacuum pumps come in a range of sizes, with 60, 80 and 100 models offered. Having used the 80 for some time, the logical step for Van der Lee was to move up to the RFL100. In theory, this would give the company the power it believed was necessary to speed up deliveries at different customer sites.

As conversations progressed, however, it became clear that the RFL100 would be over-specified for the jobs Van der Lee typically takes on. As Frank Ruijsdam, Territory Sales Manager at Gardner Denver points out: “In 2002, Van der Lee was using a G130 for most deliveries. The business has continued to fit larger packages on its vehicles, such as the S420, RFL60 and, most recently, the RFL80. These were successful solutions but it had come to the point where the next size up would be excessive. The RFL100 is capable of a flow rate up to 700m3/hr, yet none of the jobs carried out by Van der Lee would require this amount of air to be moved. It is also counterproductive to run a machine too large for its chosen application as it can actually end up damaging the equipment.”

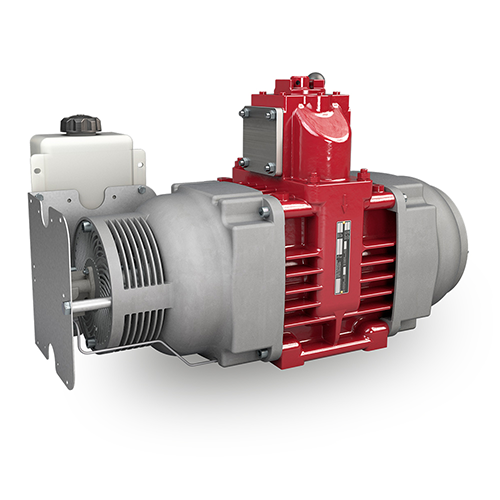

Gardner Denver’s engineers assessed the type of deliveries Van der Lee most often carried out and came up with a more efficient package using an SLS54 pump for suction alongside the hydraulically driven GD150. A pneumatically movable exhaust was also incorporated as part of the final design. This provided greater flexibility and eliminated the need for major adjustments to the vehicle’s chassis. Air-flow had originally started at 175m3/hr but Van der Lee’s most recent specification was now well over three times that figure. The GD150 would bring capacity back down to 325 m3/hr, while the SLS54 would provide sufficient vacuum power to transfer the product from its tank trucks. This work, Ruijsdam adds, highlights the range of solutions available to customers across the Gardner Denver portfolio: “Vervaeke Group is very familiar with Gardner Denver’s products and knew we would be able to come up with a solution from the existing range. This avoided the cost and delays that can be associated with a more tailored design. Having the business’s trust also meant our engineers could approach the challenge with an open mind, considering equipment Van der Lee may not have used before. It demonstrates our flexibility and scale, as well as the depth of knowledge found across Ingersoll Rand Transport Solutions”.

In terms of capacity, the new package is comparable to one used by Van der Lee in 2008. For the uninitiated this could be seen as a step back, though it has actually resulted in a more efficient solution engineered for the business’s specific needs. Running lower capacity equipment means less power is required, in turn lowering the amount of fuel used and emissions created at each delivery site. Most importantly, all parts – including vacuum pump, compressor, oil cooler, separator and moveable exhaust – were fitted without any modifications to the existing fleet. Gardner Denver knew the customer’s air requirements and its vehicle dimensions, engineering a package that would be effective without incurring additional costs for Van der Lee.

USA (EN)

USA (EN)