Flare Gas Recovery Solutions for Reducing Emissions in Oil and Gas Industries

In an age marked by a growing focus on the environment and efforts to fight climate change, the oil and gas industries are being closely examined more than ever. It's imperative that these industries adopt practices and technologies that help reduce their environmental footprint, including the emissions of greenhouse gases. Flare Gas Recovery Systems (FGRS) have emerged as a crucial player in this endeavor. Let's delve into the world of flare gas recovery and why it is vital for reducing emissions and promoting sustainable practices in the oil and gas sectors.

What is Flare Gas Recovery?

Flare Gas Recovery, often abbreviated as FGR, represents a set of specialized compression packages designed to address the challenge of gas flaring. Gas flaring is the practice of burning excess or waste gases that are produced during various industrial processes, most notably in the oil and gas sectors and chemical and petrochemical production. These industries often generate associated gases, which, if left uncontrolled, contribute significantly to the release of harmful emissions into the atmosphere. Flaring these gases has been a common and wasteful practice, causing concerns about environmental sustainability.

The Role of Flare Gas Recovery Systems

Flare Gas Recovery Systems play a pivotal role in mitigating the environmental impact of gas flaring. These systems are designed to recover and repurpose gases and emissions that would traditionally be burned during the flaring process. Key components include methane, liquefied petroleum gases (LPGs), and sulfur dioxide, all of which have a detrimental impact on the environment when released into the atmosphere.

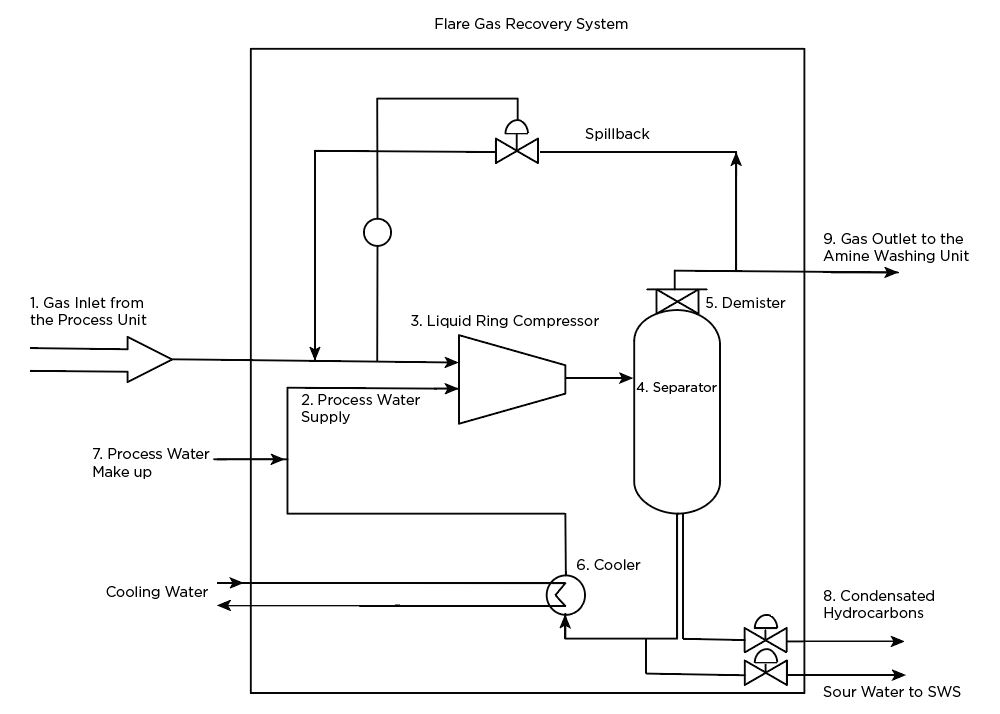

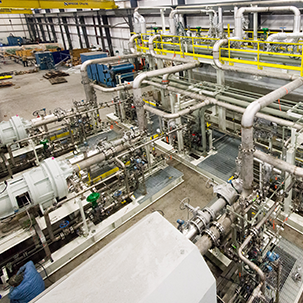

The recovery process involves capturing the gas from the flare knock-out vessel and compressing it using specialized equipment, often employing liquid ring compressors. This compression not only ensures the safe handling of these gases but also makes them available for reuse. The recovered gases can be reintegrated into the facility's fuel gas system, thereby reducing the need for external energy sources, or they can serve as valuable refinery feedstock, contributing to a more circular and sustainable economic model.

Economic Alternatives in Flare Gas Recovery

One of the key aspects of Flare Gas Recovery Systems is their economic viability. In an era where economic sustainability and environmental consciousness go hand in hand, these systems offer an attractive dual benefit. By capturing and reusing gases that would otherwise be wasted, companies in the oil and gas industries and chemical and petrochemical sectors can reduce their operational costs and environmental impact simultaneously.

The economic alternatives brought about by FGRS are significant. Companies can decrease the expenses associated with the purchase of external fuel sources, while also lessening the need for emissions-related fines and penalties. Furthermore, these recovered gases can be sold as valuable commodities or utilized to generate additional revenue streams. This economic incentive not only benefits individual companies but also contributes to a more sustainable and efficient industry as a whole.

Reducing Emissions and Promoting Sustainability

The reduction of emissions is a top priority in the fight against climate change. Flare Gas Recovery Systems are one of the cleanest solutions available to address the issue of gas flaring. They are specifically designed to capture and utilize gases that would otherwise be released into the atmosphere, thereby significantly reducing the greenhouse emissions associated with the oil and gas industries and chemical and petrochemical sectors.

By implementing these systems, companies can actively contribute to a sustainable future while also enhancing their corporate social responsibility. Reduced emissions lead to a positive environmental impact, and this, in turn, can enhance a company's reputation and relationships with environmentally conscious stakeholders.

The Environmental Impact of Gas Flaring

Gas flaring is a concerning practice that has substantial environmental repercussions. It results in the release of various pollutants, including carbon dioxide (CO2), methane (CH4), sulfur dioxide (SO2), and other hazardous chemicals into the atmosphere. These emissions contribute to air pollution, global warming, and the depletion of the ozone layer. Additionally, they can have adverse effects on human health and biodiversity.

The consequences of gas flaring extend beyond the local environment, affecting the planet on a global scale. The urgent need to reduce these emissions has led to the adoption of international agreements and regulations aimed at curbing this practice. The Kyoto Protocol and the Paris Agreement are examples of global initiatives that call for the reduction of emissions, and the adoption of Flare Gas Recovery Systems aligns with these commitments.

Evolving Technologies in Flare Gas Recovery

Flare Gas Recovery Systems continue to evolve and improve, with ongoing advancements in technology. These advancements are driven by the pressing need to address environmental concerns and the economic advantages associated with these systems. Modern FGRS are equipped with state-of-the-art components, such as high-efficiency compressors, control systems, and safety features.

Highly efficient liquid ring compressors, for example, have become a standard in FGRS. These compressors are capable of handling a wide range of gases and provide reliable compression, ensuring safe operation and minimal gas wastage. Additionally, sophisticated control systems enable real-time monitoring and adjustment, further enhancing the performance and safety of these systems.

The ongoing development of Flare Gas Recovery Systems is a testament to the industry's commitment to reducing emissions and promoting sustainable practices. Companies are continually investing in research and development to optimize the performance of these systems and make them more accessible to a wider range of industries.

Collaboration and Industry Standards

In the journey towards reducing emissions and adopting Flare Gas Recovery Systems, collaboration plays a vital role. Industry stakeholders, regulatory bodies, and technology providers are working together to develop and implement standards and best practices for flare gas recovery. These standards encompass the design, operation, and maintenance of FGRS, ensuring their effectiveness and safety.

Efforts are also being made to create incentives for companies to adopt these systems. Governments and environmental agencies are offering tax incentives, subsidies, and grants to encourage the implementation of flare gas recovery technologies. This not only benefits individual companies but contributes to broader environmental goals.

Environmental and Economic Flare Gas Recovery System Benefits

The adoption of Flare Gas Recovery Systems offers a multitude of benefits, both from an environmental and economic perspective. From an environmental standpoint, these systems directly contribute to the reduction of greenhouse gas emissions, thereby helping combat climate change and air pollution. They also reduce the release of hazardous pollutants, enhancing air quality and protecting human health and ecosystems.

Economically, FGRS represent a smart investment for companies. By recovering and reusing gases that would otherwise go to waste, companies can reduce their operational costs, decrease their dependence on external energy sources, and create new revenue streams by selling recovered gases. Additionally, the implementation of these systems can lead to a positive image boost and improved relations with environmentally conscious consumers, investors, and partners.

Conclusion

In conclusion, Flare Gas Recovery Systems are a game-changer in the quest to reduce emissions and promote sustainability in the oil and gas industries and chemical and petrochemical sectors.

These systems offer an environmentally friendly and economically viable solution to the long-standing problem of gas flaring. By capturing and repurposing gases that would otherwise be released into the atmosphere, companies can significantly reduce their environmental footprint, cut operational costs, and enhance their reputation as responsible corporate citizens.

The ongoing development and standardization of FGRS are a testament to the industry's commitment to mitigating the environmental impact of industrial processes. As the world strives to achieve ambitious climate goals, the role of Flare Gas Recovery Systems in reducing

Click Here To Learn More About Gas Flaring

.

Global (EN)

Global (EN)